|

The

Schools Marine Challenge is currently working with

schools in the South West of England... if you are a

Headteacher, teacher, or governor interested in becoming

involved with the Challenge, you can get more details by

e-mailing Nikki

Pascoe at

the British Marine Federation.

The

www.schoolsmarine.com

web site is dedicated to the Schools Marine Challenge,

now in it's third year. The Challenge provides an

excellent opportunity for schools in the South West of

England to take part in an innovative practical design

challenge. Their web site is designed to support

students and teachers as they tackle the task of

constructing working vessels, and is a useful resource,

for all pupils across the UK, hence we include it on our

website.

ALL

CONTENDERS PLEASE NOTE: Race Day 2006 will take place on

Tuesday 4th July at Roadford Lake. Put it in your

diary now!

News

: Curriculum

: Hints

& Tips : Schools

: Dates

: Gallery

The

following links to various guidance sheets are relevant

to curriculum target areas at Key Stages 3 and 4 as

well as GCSE Engineering units:-

Rules

- Make sure you check out the rules before

getting too involved with your craft. It's a

good idea to print these out and keep them handy

so you can refer to them to make sure your entry

is within the rules!

Points

Criteria - Examine this document carefully to work out

how you can achieve maximum points for your

entry

Hull

Design: Electric and IC - The hull is the most important part of your

craft and will dictate your success or otherwise

within the Challenge. Our guidance sheet will

help you through the steps you need to take to

ensure you arrive at Race Day with a fighting

chance. Combined with the information in our

Hints & Tips section, this is an essential

read for all

Hull

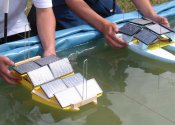

Design: Solar - The Solar Challenge offers great scope for

the design of different hull types for your

craft. Performance and handling, as well as form

and buoyancy are all reliant on your hull

design. This guidance will help you to consider

many of the options open to you.

Graphic

Products - In the modern world of sports marketing,

adopting and promoting your team identity is an

essential part of your work. You will need to

reward your sponsors with appropriate

advertising and give potential sponsors a reason

for working with you. This guidance sheet will

help you to organise your promotional campaign

Solar Craft

Guidance Notes

Design

your boat using either CAD

or hand drawn to generate Hull form. You

can print to paper to create hull line drawings

for templates, or export as CNC code.

Produce your hull from suitable modeling

material. Styrofoam, or closed cell

polyurethane foams are good. This may be used directly to mount solar panels

and propulsion system, however it would be

better to produce a shell hull, which is lighter

and not prone to water-logging.

Vacuum forming the hull directly over the

former; if using styrofoam use a release film

or paint a heat resisting surface, such as a

water based paint system. When installing

your power-train, ensure good

alignment of motor and propshaft

Top

Tips for your Solar Team - The Solar

Advantage

Coupling:

We suspect this is the key to the

outstanding performance we saw taking place. A

close up photo reveals that the alignment of

the shaft was achieved by having an adjustable

angle on the prop and motor interface. Any

friction here wastes loads of power.

Shaft: Friction busting bearing

surfaces to stop the prop shaft sliding down the

tube seem to have been simply made by using more

of the standard tube with a cable tie cut off!

Prop:

Try changing from prop to prop and then

running against the clock. Is there any

significant difference between standard (orange

surface piercing) and the more usual red propellers. You

will probably find one prop is smoother running.

If you do, that prop is probably best suited to your

hull energy requirements.

Motor

details: Standard Low Inertia

Solar

Panels: Standard x 6 wire in series

Times over a distance of

10 metres

|

Bright Sunlight

|

1.45 m/sec

|

Sunlight

|

0.9 m/sec

|

Daylight

|

0.36 m/sec

|

Failing light

|

0.24 m/sec

|

Hull:

Design on a larger scale than Solar either as a vacuum

forming or as an entry composite project from a mould

and pattern. Alternatively you can request one to get

you going, however you would not gain as many points

available for the hull design section of the

competition.

Powertrain: Make sure you have a coupling to

the prop shaft that does not waste valuable power, make

one that keeps the motor and prop shaft in perfect

alignment. Our prototype used a brass rod drilled and

tapped. Fix the motor so that you can adjust its angle

slightly. A popular method is using an aluminium plate

that can be bent slightly and slots for the screw holes

in the motor.

Layout:

Balance your boat; you do not want heavy bows! Motor mounting

tip: ONLY USE SHORT SCREWS MAXIMUM

LENGTH 6MM. Longer screws will catch the motor

armature!

Radio gear can use the same power supply as the

motor. Keep in a watertight compartment.

Battery:

Quick

access to this will be required on Race Day so make

access easy.

Speed controller: You don’t really need one

as you will be going flat out all the time. A slide

switch can be linked to the servo to give forward and

reverse, but even that may be a luxury

Build

Your Own Solar Test Tank

One

of the problems with testing your craft is finding a

suitable place to put your boat

through

it's paces. If the staff-room kitchen sink is too small

why not consider constructing your own testing tank.

It's not as difficult as it might seem, as long as you

keep it to a realistic size and bear a number of things

in mind!

-

is there a suitable level surface available?

- what size will allow for meaningful testing?

- how will the tank be filled?

- how will the tank be emptied?

- are you able to assemble and disassemble quickly

at the end of the school day?

- what health and safety impications are involved?

The

tank we will be using for the Solar challenge can be

easily constructed from cheap materials to give you

plenty of opportunity for dynamic testing.

Basic materials are: 12’

Fence rails, Builder polythene sheeting (damp proof

membrane available from stores such as Wickes)

Use

the drawing and photograph as a guide. Beware of

constructing something too large as it will hold a

considerable volume of water. Design and calculate your

tank before becoming too ambitious!

The

image below shows the cross section through the tank.

The corners of the tank have to be reinforced and

mechanically fixed (screwed together) to take the

pressure of the water in the tank. Although this is only

shallow there is enough pressure to push the corners out

if they are not secured fully.

You can use this method to make a simple test tank that

can be of any length or breadth to test your craft

in. Make sure

that the area that you use is free of sharp objects so

that you do not puncture your liner.

School

Teams: Let us know how you get on. You can e-mail us

some pictures of your pool. You could even hold your own

Solar Challenge prior to Race Day to decide which boat

will represent your school.

Marine

Challenge Schools 2004/5

The

following schools are entered in the 3rd Schools Marine

Challenge. Don't forget to send us reports on your

progress; photos of your team and your craft, team

diaries, news of sponsorhip arrangements etc.

Publicising your work is an important part of the

Challenge. You can e-mail items for your school page via

info@schoolsmarine.com.

|

All Saints

Church of England School, Weymouth

Brixham Community College

Budmouth Technology College, Weymouth

Colyton Grammar School

Coombe Dean School, Plymouth

Great Torrington Community School

Hele's School, Plymouth

Helston School and Community College

Holsworthy Community College

Ivybridge Community College

Kingsbridge Community College

|

Launceston

College

Lipson Community College, Plymouth

Liskeard School and Community College

Newquay Tretherras School

Notre Dame RC School, Plymouth

Oakmead College of Technology, Bournemouth

Pilton Community College

St Boniface's RC College, Plymouth

Teignmouth Community College

The King's School, Ottery St Mary

West Exe Technology College

|

Electric Charger

The battery charger is as essential to the electric

challenge as petrol is to the internal combustion one.

You can buy a charger but they can be

expensive or you can put together a simple electronics

project to make your own for less than £1.50p

A Charging Circuit

Charging batteries from a 12volt car battery to the

7.2volt 6 cell battery pack is relatively straight

forward.

The theory is as follows: -

The rating for the 6 cell battery is 13000mAh

therefore to charge the battery in 1/2hr; the current

flow has to be 2.6Amps. (1.3 x 2 = 2.6)

The circuit has to lose approx. 4.8V

The battery is 1.2volts per cell, 6 cells = 7.2V [12

– 7.2 = 4.8]

Therefore, using Ohms law:-

V/I=R 4.8 / 2.6 = 1.85 Ohms

If

we use a 1 Ohm resistor the power required is: V x I =

W (4.8x2.6= approx. 12.5Watts)

The resistor we recommend is rated at 25Watts so

running this component at half its rating will ensure

it doesn’t heat up enough to burn. However if the

battery is left on charge for extended periods, above

the calculated 1/2hour, then the cells will get hot so

this is not recommended.

An aluminium clad wire-wound resistor, code 62-8106

from Rapid Electronics Ltd costs only £1.30.

We would recommend that you include an in-line fuse

with the resistor, or on the negative wire, for safety

reasons.

It

is recommended that the whole circuit is

mounted on a suitable plate such as an aluminium alloy

with large croc clips connecting the 12volt car

battery to the circuit. Care must be taken to ensure

the wire is also thick enough to be rated to 3amps.

The fuse can be approximately 5Amps.

Solar

Cola sponsor this website.

Available

at all good supermarkets from June 06.

|