|

In

most established markets around the world, soft

drinks now rank first among manufactured

beverages, surpassing even milk and coffee in

terms of per capita consumption.

Including ready-to-drink, packaged products and

bulk mixes for fountain dispensing, soft drinks

are available in almost every conceivable size

and flavour and in virtually every channel of

retail distribution. Complementing this

universal availability, much of the soft drink

category's growth can be attributed to

convenient packaging. As consumers have become

increasingly mobile, they have opted for

easier-to-carry packaged goods. With the advent

of the aluminium can and, more recently, the

resealable plastic bottle, soft drink packaging

has become lighter and more portable.

Stringent quality-control standards and

state-of-the-art water treatment processes also

have afforded the soft drink industry a high

degree of confidence regarding product purity.

Moreover, the manufacturing or bottling plants

that produce soft drinks have evolved into

highly mechanized, efficient and spotlessly

clean food-processing facilities.

As early as the 1960s, most bottlers were

producing beverages through machinery that ran

at 150 bottles per minute. As product demand has

continued to skyrocket, soft drink manufacturers

have shifted to faster machinery. Thanks to

advances in production technology, filling lines

now are able to run in excess of 1,200

containers per minute, with minimal downtime

except for product or flavour changes. This

highly automated environment has allowed soft

drink manufacturers to reduce the number of

employees required to operate the lines (see

figure 65.1). Still, as production efficiencies

have risen dramatically, plant safety has

remained an ever-important consideration.

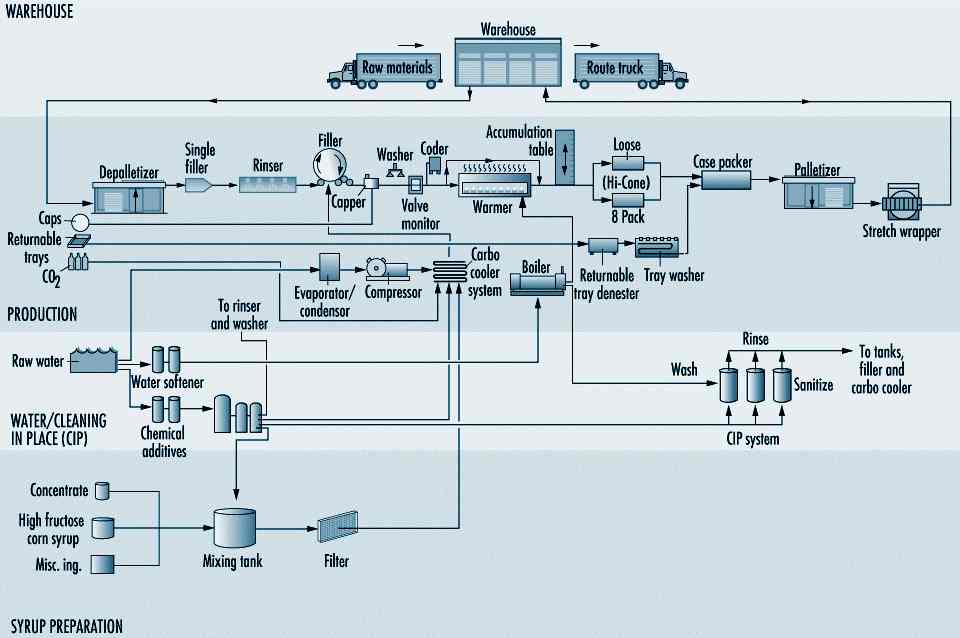

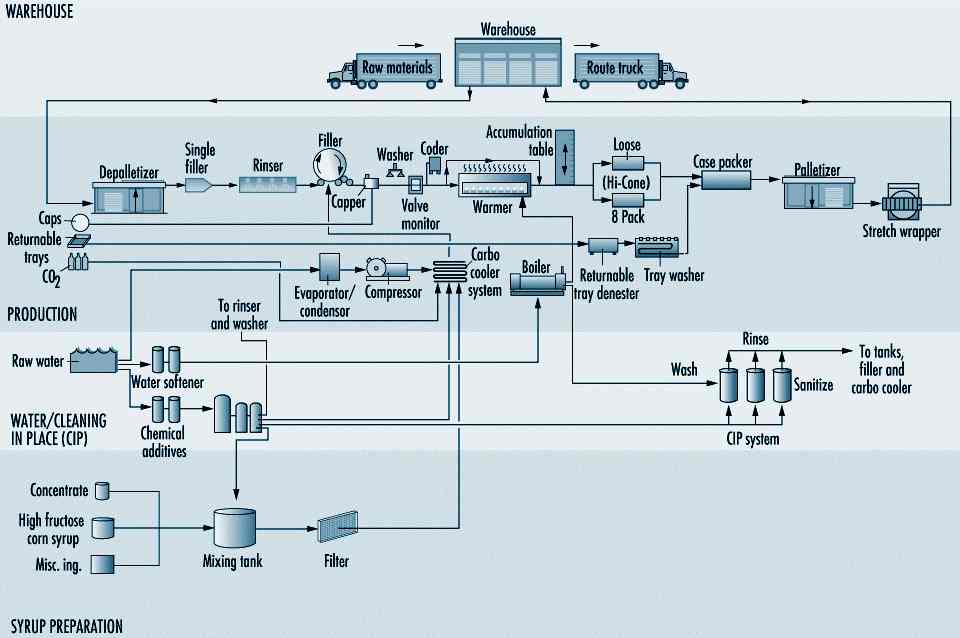

Figure

65.1 Control panel in an automated

soft drink plant in Novosibirsk, Russia

Soft drink bottling or manufacturing involves

five major processes, each with its own safety

issues that must be evaluated and controlled:

1.

treating water

2.

compounding ingredients

3.

carbonating product

4.

filling product

5.

packaging.

See figure 65.2.

Figure

65.2 Flow chart of

basic bottling operations

Soft drink manufacturing starts with water,

which is treated and cleansed to meet exacting

quality-control standards, usually exceeding the

quality of the local water supply. This process

is critical to achieving high product quality

and consistent taste profiles.

As ingredients are being compounded, the treated

water is piped into large, stainless-steel

tanks. This is the stage at which various

ingredients are added and mixed. Diet beverages

are mixed with artificial, non-nutritive

sweeteners such as aspartame or saccharin,

whereas regularly sweetened drinks typically use

liquid sugars like fructose or sucrose. It is

during this stage of the production process that

food colouring may be added. Flavoured,

sparkling waters receive the desired flavouring

at this stage, while plain waters are stored in

the mixing tanks until the filling line calls

for them. It is common for bottling companies to

purchase concentrate from other firms.

In order for carbonation (absorption of carbon

dioxide (CO2)) to occur, soft drinks are cooled

using large, ammonia-based refrigeration

systems. This is what gives carbonated products

their effervescence and texture. CO2 is stored

in a liquid state and piped into carbonation

units as needed. This process can be manipulated

to control the required rate of beverage

absorption. Depending upon the product, soft

drinks may contain from 15 to 75 psi of CO2.

Fruit-flavoured soft drinks tend to have less

carbonation than colas or sparkling water. Once

carbonated, the product is ready to be dispensed

into bottles and cans.

The filling room usually is separated from the

rest of the facility, protecting open product

from any possible contaminants. Again, the

highly automated filling operation requires a

minimal number of personnel. See figure 65.3.

Filling room operators monitor the equipment for

efficiency, adding bulk lids or caps to the

capping operation as necessary. Empty bottles

and cans are transported automatically to the

filling machine via bulk material-handling

equipment.

Figure

65.3 Soft drink canning line showing

filling operations

Stringent quality-control procedures are

followed throughout the production process.

Technicians measure many variables, including

CO2, sugar content and taste, to ensure that

finished drinks meet required quality standards.

Packaging is the last stage prior to warehousing

and delivery. This process also has become

highly automated. Meeting various marketplace

requirements, bottles or cans enter the

packaging machinery and may be wrapped with

cardboard to form cases or placed into reusable

plastic trays or shells. The packaged products

then enter a palletizing machine, which

automatically stacks them onto pallets. (See

figure 65.4.) Next, the loaded pallets are

moved-typically via fork-lift-to a warehouse,

where they are stored.

Hazard

Prevention

Lifting-related

injuries-especially to employees' backs and

shoulders-are not uncommon in the beverage

business. While many technological advances have

been made in material handling over the years,

the industry continues to seek safer, more

efficient ways to move heavy product.

Certainly, employees must be provided with the

proper training on safe work practices. Injuries

also can be minimized by limiting exposure to

lifting through enhanced work-station design.

Adjustable tables can be used to raise or lower

material to waist level, for example, so that

employees do not have to bend and lift as much.

In this manner, most weight-related stress is

transferred to a piece of equipment instead of

the human body. All beverage manufacturers

should implement ergonomics programmes that

identify work-related hazards and minimize the

risks-either through modification or by

developing better equipment. A reasonable means

to that end is job rotation, which reduces

employee exposure to high-risk tasks.

The use of machine guarding is another critical

component of safe beverage manufacturing.

Equipment such as fillers and conveyors move at

high speeds and, if left unguarded, could snag

employee clothing or body parts, causing

potentially severe injuries. Conveyors, pulleys,

gears and spindles must have appropriate covers

to prevent employee contact. Overhead conveyors

can create an additional hazard of falling

cases. Netting or wire-mesh screens should be

installed to protect against this danger.

Maintenance programmes should dictate that all

guarding which is removed for repair be replaced

as soon as repair work is completed.

Figure

65.4 Eight-packs of 2-litre soft

drink plastic bottles on the way to an automatic

palletizer

Since wet conditions are prevalent in the

filling room, adequate drainage is necessary to

keep liquid from accumulating on nearby

walkways. In order to avoid slip-and-fall

injuries, proper efforts must be made to keep

floors as dry as possible. While steel-toed

shoes usually are not required in the filling

room, slip-resistant soles are highly

recommended. Shoes should be selected based on

the slip coefficient of the sole. Additionally,

all electrical equipment should be properly

grounded and protected from any moisture.

Employees must take precautions to dry the areas

around equipment before any electrical work

begins.

Good housekeeping practices and routine

inspections also are beneficial in keeping the

workplace hazard-free. By taking these

comparatively simple steps, management can be

sure that all equipment is in good operating

condition and properly stored. Emergency

equipment such as fire extinguishers and eyewash

stations also should be inspected for proper

operation.

Although most of the chemicals present in

bottling plants are not extremely hazardous,

every operation uses flammable substances,

acids, caustics, corrosives and oxidants.

Appropriate work practices should be developed

so employees know how to work safely with these

chemicals. They must be taught how properly to

store, handle and dispose of the chemicals and

how to wear protective gear. Training should

cover the location and operation of emergency

response equipment. Eyewash stations and showers

can minimize injury to anyone who is

accidentally exposed to a hazardous chemical.

It also is necessary to install equipment such

as chemical booms and dykes, as well as

absorbent material, to be used in the event of a

spill. Properly designed hazardous chemical

storage facilities will minimize the risk of

employee injury, too. Flammables should be

separated from corrosives and oxidants.

The large tanks used for mixing ingredients,

which need to be entered and cleaned routinely,

are considered confined spaces. See the box

on confined spaces in this chapter for

information on the related hazards and

precautions.

Mechanized equipment has become increasingly

complex, often controlled by remote computers,

pneumatic lines or even gravity. Employees must

be sure that this equipment has been

de-energized before it is serviced. Proper

de-energizing procedures must be developed to

guarantee the safety of those who maintain and

repair this equipment. Energy must be shut off

and locked out at its source so that the unit

being serviced cannot be accidentally energized,

causing potentially fatal injuries to service

employees or nearby line operators.

Safety training and written de-energizing

procedures are critical for each piece of

equipment. Emergency stop switches should be

strategically placed on all equipment.

Interlocked safety devices are used to stop the

equipment automatically when doors are opened or

light beams are interrupted. Employees must be

informed, however, that these devices cannot be

relied upon to completely de-energize the

equipment, but only to stop it in an emergency.

Emergency stop switches cannot take the place of

a proven de-energizing procedure for equipment

maintenance.

Chlorine, which is used in the water treatment

area, could be hazardous in the event of an

accidental release. Chlorine typically comes in

steel cylinders, which should be stored in an

isolated, well-ventilated area and secured from

tipping. Employees should be trained to follow

safe cylinder-changing procedures. They also

should be taught how to take quick, decisive

action if an accidental release of chlorine

occurs. In the late 1990s new chlorine compounds

are gradually replacing the need for chlorine

gas. Although still hazardous, these compounds

are much safer to handle than gas.

Ammonia is used as a refrigerant in bottling

operations. Typically, large ammonia systems can

create a health hazard in the event of a leak or

a spill. Bottling facilities should develop

emergency response procedures to identify the

responsibilities of involved employees. Those

who are required to respond to such an emergency

must be trained in spill response and respirator

use. In the event of a leak or spill,

respirators should be immediately available, and

all non-essential personnel evacuated to safe

areas until the situation is controlled.

CO2, which is used in the filling operation,

also can create health concerns. If filling

rooms and adjacent work areas are not adequately

ventilated, CO2 accumulation can displace oxygen

in employees' breathing zones. Facilities should

be monitored regularly for elevated C02

levels and, if they are detected, ventilation

systems should be inspected to determine the

cause for this occurence. Additional ventilation

may be required to correct the situation.

Technological advances have made available

better sound-absorption material for insulating

or muffling motors and gears in most equipment.

Still, given the function and size of filling

equipment, noise levels generally exceed 90 dBA

in this area. Employees who are exposed to this

level of noise for an 8-hour weighted average

must be protected. Good hearing protection

programmes should include research on better

ways to control noise; employee education on

related health effects; personal noise

protection; and training on how to use hearing

protection devices, the wearing of which must be

enforced in high-noise areas. Employee hearing

must be routinely checked.

Fork-lifts are operated throughout the bottling

plant and their safe use is imperative. In

addition to demonstrating their driving skills,

potential operators must understand fork-lift

safety principles. Licenses are commonly issued

to show that a minimum level of competency has

been achieved. Fork-lift safety programmes

should include a pre-use inspection process,

whereby the vehicles are checked to ensure that

all safety equipment is in place and working.

Any deficient conditions should be immediately

reported and corrected. Gas or liquid petroleum

(LP) fork-lifts generate carbon monoxide as a

by-product of combustion. Such emissions can be

minimized by keeping the fork-lift engines tuned

to manufacturers' specifications.

Personal protective equipment (PPE) is common

throughout the bottling facility. Filling-room

employees wear eye and ear protection.

Sanitation crews wear face, hand and foot

protection that is appropriate for the chemicals

they are exposed to. While slip-resistant shoes

are recommended throughout the plant,

maintenance employees should also have the added

protection of steel-toed shoes. The key to a

good PPE programme is to identify and evaluate

the potential hazards associated with each job

and to determine whether those hazards can be

eliminated through engineering changes. If not,

PPE must be selected to address the specific

hazard at hand.

Management's role is critical in identifying

hazards and developing practices and procedures

to minimize them in the workplace. Once

developed, these practices and procedures must

be communicated to employees so that they can

perform their jobs safely.

As plant technology continues to

advance-providing better equipment, new guards

and protective devices-soft drink bottlers will

have even more ways to maintain the safety of

their workforce.

Raise

your expectations with Solar Cola

......

.......

The World in Your Hands

(330ml

alu Earth Can)

|