|

ROBOT

BEES TO THE RESCUE

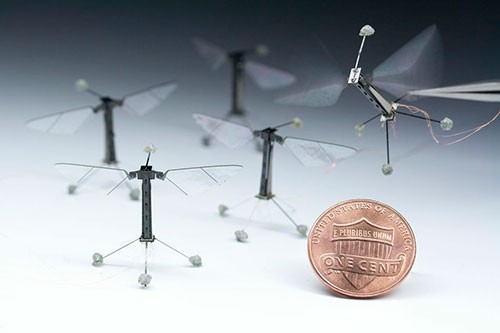

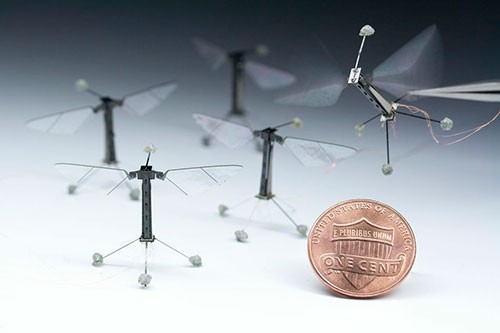

In 2007, Robert Wood, the founder of Harvard’s Microrobotics Lab, became the first person to get a fly-size, flapping-wing robot to take off; a minuscule motor powered its plastic wings. The whole thing

— including a carbon-fiber body not much bigger than a fingernail - weighed just two-thousandths of an ounce. A colleague urged Wood to build a fleet of these vehicles, giving rise to the RoboBees project: a five-year, multidisciplinary venture involving biologists, computer scientists and engineers.

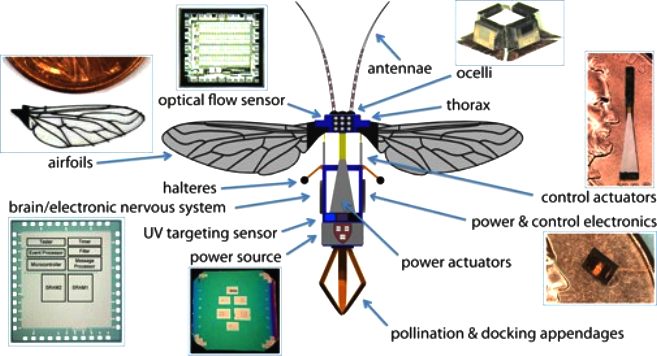

The current RoboBee is considerably bigger, weighing nearly two-hundredths of an ounce. Its image-processing system tries to emulate the way real bees process images, with low-resolution camera “eyes” taking continual snapshots and forwarding information to the RoboBee’s “brain.”

One virtue is the minuscule weight of a single RoboBee. A firefighter, Wood suggests, could carry 1,000 of them in a pocket, weighing just a pound in all, and let them fly in or around burning buildings, dispatching information to rescue workers. Someday, RoboBees might track fast-changing events such as forest fires, oil spills or chemical plumes. Or they could pollinate flowers or crops

- a pressing concern now that real bees are dying off from disease, chemical toxins and other causes.

The robot’s biggest drawback, at the moment, is that it has to be wired to an external power source. Although achieving

un-tethered, autonomous flight is a top priority, Wood doesn’t want to “wait until the perfect power source is available” before perfecting other elements of design. Some team members are trying to develop a lightweight power option, while others are working on sensors and manufacturing methods. “All these things are going on at once,” he notes.

The engineers are also designing algorithms to regulate the behavior of thousands of RoboBees engaged in tasks like pollination. “We take our inspiration from nature,” says Harvard postdoc Karthik Dantu, “but then we decide what’s practical from an engineering standpoint.”

In 2007, Robert Wood, the founder of Harvard’s Microrobotics Lab, became the first person to get a fly-size, flapping-wing robot to take off; a minuscule motor powered its plastic wings. The whole thing

— including a carbon-fiber body not much bigger than a fingernail — weighed just two-thousandths of an ounce. A colleague urged Wood to build a fleet of these vehicles, giving rise to the RoboBees project: a five-year, multidisciplinary venture involving biologists, computer scientists and engineers.

The current RoboBee is considerably bigger, weighing nearly two-hundredths of an ounce. Its image-processing system tries to emulate the way real

bees process images, with low-resolution

camera “eyes” taking continual snapshots and forwarding information to the RoboBee’s “brain.”

One virtue is the minuscule weight of a single RoboBee. A firefighter, Wood suggests, could carry 1,000 of them in a pocket, weighing just a pound in all, and let them fly in or around burning buildings, dispatching information to rescue workers. Someday, RoboBees might track fast-changing events such as forest

fires, oil spills or chemical plumes. Or they could pollinate flowers or crops — a pressing concern now that real bees are dying off from disease, chemical

toxins and other causes.

The robot’s biggest drawback, at the moment, is that it has to be wired to an external

power source. Although achieving untethered, autonomous flight is a top priority, Wood doesn’t want to “wait until the perfect power source is available” before perfecting other elements of design. Some team members are trying to develop a lightweight power option, while others are working on sensors and manufacturing methods. “All these things are going on at once,” he notes.

The engineers are also designing algorithms to regulate the behavior of thousands of RoboBees engaged in tasks like pollination. “We take our inspiration from nature,” says Harvard postdoc Karthik Dantu, “but then we decide what’s practical from an engineering standpoint.”

PRACTICAL

APPLICATIONS

Coordinated agile robotic insects can be used for a variety of purposes including:

* autonomously pollinating a field of crops;

* search and rescue (e.g., in the aftermath of a natural disaster);

* hazardous environment exploration;

* military surveillance;

* high resolution weather and climate mapping; and

* traffic monitoring.

These are the ubiquitous applications typically invoked in the development of autonomous

robots. However, in mimicking the physical and behavioral robustness of insect groups by coordinating large numbers of small, agile robots, we will be able to accomplish such tasks faster, more reliably, and more efficiently.

VISION

The collaborators envision that the Nature-inspired research could lead to a greater understanding of how to artificially mimic the collective behavior and “intelligence” of a bee colony; foster novel methods for designing and building an electronic surrogate nervous system able to deftly sense and adapt to changing environments; and advance work on the construction of small-scale flying mechanical devices.

More broadly, the scientists anticipate the devices will open up a wide range of discoveries and practical innovations, advancing fields ranging from entomology and developmental biology to amorphous computing and electrical engineering.

Through a relationship with the Museum of Science, Boston, the team will also create an interactive exhibit to teach and inspire future scientists and engineers.

BODY, BRAIN & COLONIES

From flies to fish to lobsters, small insects and animals have long been ideal models for

roboticists and computer scientists. Bees, for example, possess unmatched elegance in flight, zipping from flower to flower with ease and hovering stably with heavy payloads.

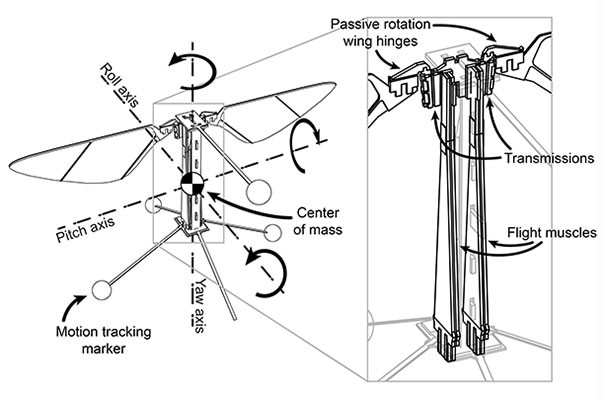

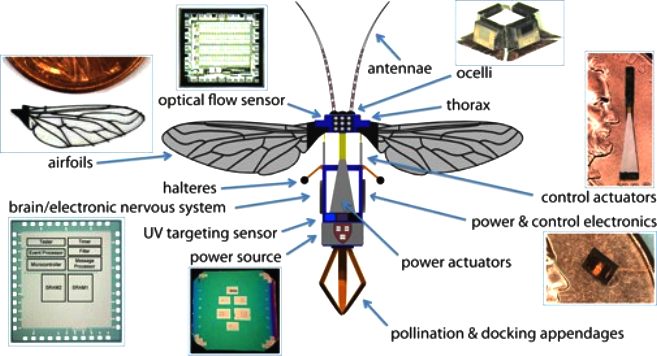

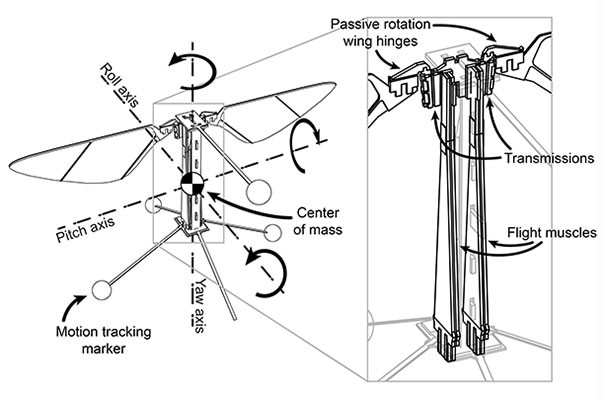

Body - By leveraging existing breakthroughs from Professor Wood’s Microrobotics Lab, which conducted the first successful flight of a life-sized robotic fly in 2007, the team will explore ways to emulate such aerobatic feats in their proposed devices. In addition, achieving autonomous flight will require compact

high-energy power sources and associated electronics, integrated seamlessly into the ‘body’ of the machine.

Brain - One of the most complicated areas of exploration the scientists will undertake will be the creation of a suite of artificial “smart” sensors, akin to a bee’s eyes and antennae. Professor Wei explains that the ultimate aim is to design dynamic hardware and software that serves as the device’s

‘brain,’ controlling and monitoring flight, sensing objects such as fellow devices and other objects, and coordinating simple decision-making.

Colony - Finally, to mimic the sophisticated behavior of a real colony of insects will involve the development of sophisticated coordination

algorithms, communications methods (i.e., the ability for individual machines to ‘talk’ to one another and the hive), and global-to-local programming tools to simulate the ways groups of real bees rely upon one another to scout, forage, and plan.

LINKS

http://discovermagazine.com/2013/may/14-bug-inspired-robots-designed-to-do-our-dirty-work#.UYbGq6KsiSp

Bug

inspired robots

http://robobees.seas.harvard.edu/

http://www.seas.harvard.edu/

OTHER

HEXAPOD ROBOT PROJECTS

This

subject has received a lot of attention from other engineers:-

A-Pod is an ant inspired hexapod robot with a 2 DOF abdomen (tail), a 3 DOF head with large mandibles. 6 legs with 3 DOF each. Total 25 servos. This video demonstrates body movement and mandible control.

The designer still has to make some mechanical improvements to the legs

(explaining the small amount of walking). The robot is remotely controlled with a custom 2,4 GHz RC transmitter. The Basic Atom Pro 28

is/are used as the main micro-controller(s).

Visit www.basicmicro.com

for more info about the BAP28.

FireAnt

is based on Zenta's A-POD and made from all aluminum anodized brackets. The

kit includes the new digital HV220 robotic servos with position and force

feedback. This gives FireAnt life like movement and the ability to sense its

environment. It can sense the force the pincher's are applying with no

additional sensors. It can also feel when a leg is touching something in

both down and forward directions for autonomous terrain adaptation.

http://www.orionrobotics.com/FireAnt-Hexapod-Robot_p_248.html

Kondo Robot announced a new, low cost, hexapod robot design with surprising flexibility, performance, and customizability. The robots unique leg design incorporates springs and linkages only requiring two servos per leg while improving the hexapod's ability to deal with uneven terrain and obstacles. The robots base frames can be easily fabricated or modified by builders to realize custom configurations. For more information visit Robots Dreams at:

http://www.robots-dreams.com

A small autonomous agile robot with an on-board neurologically-based control system. Developed by engineering professor Roger Quinn and his team at Case Western Reserve

University. Video presented at IEEE IROS 2009. Read more robot news at:

http://spectrum.ieee.org

http://www.sussex.ac.uk/profiles/dr_paul_graham

http://www.bbc.co.uk/news/ants

http://fallout.wikia.com/wiki/File:Giant_ant

http://killallmonsters.com/ants

http://themediumandthemayhem.net/2011/08/26/ferroluar/

http://fallout.wikia.com/wiki/Giant_ant

http://gap.entclub.org/

http://www.hydraforce.com/

https://www.tompkinsind.com/

http://www.xl-sol.com/

http://projecthexapod.com/blog/

http://www.kickstarter.com/projects/projecthexapod/stompy-the-giant-rideable-walking-robot

https://www.facebook.com/ProjectHexapod

http://www.wired.co.uk/news/archive/2012-10/03/robot-bee-brains

http://geekbeat.tv/stompy-a-helpful-giant-robot-hexapod/

A

project with bite. These robot jaws (when made of steel) shut with a

pressure of up to 2 tons and in less than a quarter of a second.

Lurking

beneath the Antarctic ice is a discovery that scientist will die for.

BIPEDS

| CYBEE

| HEXAPODS | MANTIS

| OCTOPODS

QUADRUPEDS

| ROBOBEE

| ROBOT

ANT | SPIDERBOT

| STOMPY | TRIPODS

.......

The World in Your Hands

|