|

VW

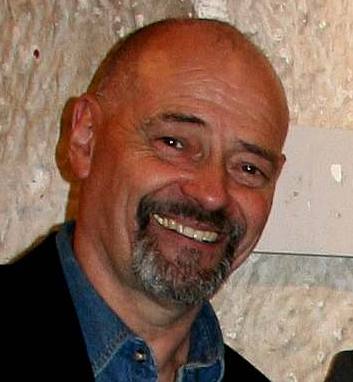

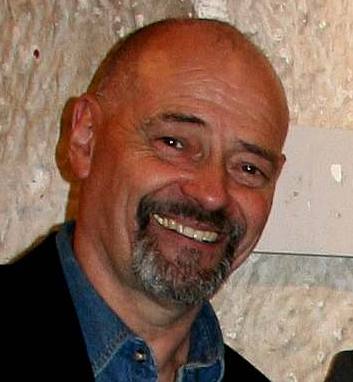

CAMPER COMBI VAN - In this picture a veteran welder is repairing the

Miss

Ocean tour bus, a Volkswagen bus that is set to be one of the finest

surfing wagons around. A new chassis member is being welded into

position using one of the latest digital MIG machines from R-Tech.

Copyright photograph © 5 December 2016. You will need the permission of

Bluebird Marine Systems to use this photograph except for research,

educational or media review purposes.

The

ability to join two pieces of metal to produce a strong

and reliable joint, in the comfort of your garage, is

one of the miracles of the modern age. Without

this ability (agreed this is dependent on the skill of

the operator) many brilliant home build vehicles would

not see the light of day. I was self taught,

having read just about everything I could lay my hands on about the

theory. My first welder was an Oxford Bantam arc welder - hence

rods, which was provided a smooth flow. Having taught myself to

weld, I completed a short course at Lewes

College to hone up my skills. To complete my first car, I invested in a MIG which speeded up the welding process

and eliminated chipping. I was hooked. MIG was the future of

welding, but gas welding also had a lot going for it until I discovered

TIG welding.

WELDING HISTORY

Welding can trace its historic development back to

ancient times. The earliest examples come from the

Bronze Age. Small gold circular boxes were made by

pressure welding lap joints together. It is estimated

that these boxes were made more than 2000 years ago.

During the Iron Age the Egyptians and people in the

eastern Mediterranean area learned to weld pieces of

iron together. Many tools were found which were made

approximately 1000 B.C.

MIDDLE

AGES

During the Middle Ages, the art of blacksmithing was

developed and many items of iron were produced which

were welded by hammering. It was not until the 19th

century that welding, as we know it today was invented.

1800

Edmund Davy of England is credited with the discovery of

acetylene in 1836. The production of an arc between two

carbon electrodes using a battery is credited to Sir

Humphry Davy in 1800. In the mid-nineteenth century, the

electric generator was invented and arc lighting became

popular. During the late 1800s, gas welding and cutting

was developed. Arc welding with the carbon arc and metal

arc was developed and resistance welding became a

practical joining process.

MIG

and stick arc welding methods each have their own advantages and

disadvantages. Stick welding is useful in shipyards where strong gusts

of wind would blow away any shielding gas. The rolls of MIG wire rust if

not used frequently, whereas welding rods get damp so that the composite

shroud prevents an effective arc being struck until the rod warms up

from sticking on the work piece creating a short that heats the rod up.

Copyright photograph © 5 December 2016. You will need the permission of

Bluebird Marine Systems to use this photograph except for research,

educational or media review purposes.

1880

Auguste De Meritens, working in the Cabot Laboratory in

France, used the heat of an arc for joining lead plates

for storage batteries in the year 1881. It was his

pupil, a Russian, Nikolai N. Benardos, working in the

French laboratory, who was granted a patent for welding.

He, with a fellow Russian, Stanislaus Olszewski, secured

a British patent in 1885 and an American patent in 1887.

The patents show an early electrode holder. This was the

beginning of carbon arc welding. Bernardos' efforts were

restricted to carbon arc welding, although he was able

to weld iron as well as lead. Carbon arc welding became

popular during the late 1890s and early 1900s.

1890

In 1890, C.L. Coffin of Detroit was awarded the first

U.S. patent for an arc welding process using a metal

electrode. This was the first record of the metal melted

from the electrode carried across the arc to deposit

filler metal in the joint to make a weld. About the same

time, N.G. Slavianoff, a Russian, presented the same

idea of transferring metal across an arc, but to cast

metal in a mold.

As

part of a series of Youtube tutorial videos, Leo walks us through the

basics of technologies used in the construction of the

Elizabeth

Swann the world's

fastest hydrogen

powered ship. This installment is how to weld.

1900

Approximately 1900, Strohmenger introduced a coated

metal electrode in Great Britain. There was a thin

coating of clay or lime, but it provided a more stable

arc. Oscar Kjellberg of Sweden invented a covered or

coated electrode during the period of 1907 to 1914.

Stick electrodes were produced by dipping short lengths

of bare iron wire in thick mixtures of carbonates and

silicates, and allowing the coating to dry.

Meanwhile, resistance welding processes were developed,

including spot welding, seam welding, projection welding

and flash butt welding. Elihu Thompson originated

resistance welding. His patents were dated 1885-1900. In

1903, a German named Goldschmidt invented thermite

welding that was first used to weld railroad rails.

Oxy-acetylene

gas welding

Gas welding and cutting were perfected during this

period as well. The production of oxygen and later the

liquefying of air, along with the introduction of a blow

pipe or torch in 1887, helped the development of both

welding and cutting. Before 1900, hydrogen and

coal gas

were used with oxygen. However, in about 1900 a torch

suitable for use with low-pressure acetylene was

developed.

World War I brought a tremendous demand for armament

production and welding was pressed into service. Many

companies sprang up in America and in Europe to

manufacture welding machines and electrodes to meet the

requirements.

1919

Immediately after the war in 1919, twenty members of the

Wartime Welding Committee of the Emergency Fleet

Corporation under the leadership of Comfort Avery Adams,

founded the American Welding Society as a nonprofit

organization dedicated to the advancement of welding and

allied processes.

Alternating current was invented in 1919 by C.J. Holslag;

however it did not become popular until the 1930s when

the heavy-coated electrode found widespread use.

A

portable

gas welding rig

1920

In 1920, automatic welding was introduced. It utilized

bare electrode wire operated on direct current and

utilized arc voltage as the basis of regulating the feed

rate. Automatic welding was invented by P.O. Nobel of

the General Electric Company. It was used to build up

worn motor shafts and worn crane wheels. It was also

used by the automobile industry to produce rear axle

housings.

During the 1920s, various types of welding electrodes

were developed. There was considerable controversy

during the 1920s about the advantage of the heavy-coated

rods versus light-coated rods. The heavy-coated

electrodes, which were made by extruding, were developed

by Langstroth and Wunder of the A.O. Smith Company and

were used by that company in 1927. In 1929, Lincoln

Electric Company produced extruded electrode rods that

were sold to the public. By 1930, covered electrodes

were widely used. Welding codes appeared which required

higher-quality weld metal, which increased the use of

covered electrodes.

During the 1920s there was considerable research in

shielding the arc and weld area by externally applied

gases. The atmosphere of oxygen and nitrogen in contact

with the molten weld metal caused brittle and sometime

porous welds. Research work was done utilizing gas

shielding techniques. Alexander and Langmuir did work in

chambers using hydrogen as a welding atmosphere. They

utilized two electrodes starting with carbon electrodes

but later changing to tungsten electrodes. The hydrogen

was changed to atomic hydrogen in the arc. It was then

blown out of the arc forming an intensely hot flame of

atomic hydrogen during to the molecular form and

liberating heat. This arc produced half again as much

heat as an oxyacetylene flame. This became the atomic

hydrogen welding process. Atomic hydrogen never became

popular but was used during the 1930s and 1940s for

special applications of welding and later on for welding

of tool steels.

H.M. Hobart and P.K. Devers were doing similar work but

using atmospheres of argon and helium. In their patents

applied for in 1926, arc welding utilizing gas supplied

around the arc was a forerunner of the gas tungsten arc

welding process. They also showed welding with a

concentric nozzle and with the electrode being fed as a

wire through the nozzle. This was the forerunner of the

gas metal arc welding process. These processes were

developed much later.

R-TECH -

We loved the feel on this dc inverter based machine.

1930

Stud welding was developed in 1930 at the New York Navy

Yard, specifically for attaching wood decking over a

metal surface. Stud welding became popular in the

shipbuilding and construction industries.

The automatic process that became popular was the

submerged arc welding process. This "under

powder" or smothered arc welding process was

developed by the National Tube Company for a pipe mill

at McKeesport, Pennsylvania. It was designed to make the

longitudinal seams in the pipe. The process was patented

by Robinoff in 1930 and was later sold to Linde Air

Products Company, where it was renamed Unionmelt®

welding. Submerged arc welding was used during the

defense buildup in 1938 in shipyards and in ordnance

factories. It is one of the most productive welding

processes and remains popular today.

1940

Gas tungsten arc welding (GTAW) had its beginnings from

an idea by C.L. Coffin to weld in a nonoxidizing gas

atmosphere, which he patented in 1890. The concept was

further refined in the late 1920s by H.M.Hobart, who

used helium for shielding, and P.K. Devers, who used

argon. This process was ideal for welding magnesium and

also for welding stainless and aluminum. It was

perfected in 1941, patented by Meredith, and named

Heliarc® welding. It was later licensed to Linde Air

Products, where the water-cooled torch was developed.

The gas tungsten arc welding process has become one of

the most important.

The gas shielded metal arc welding (GMAW) process was

successfully developed at Battelle Memorial Institute in

1948 under the sponsorship of the Air Reduction Company.

This development utilized the gas shielded arc similar

to the gas tungsten arc, but replaced the tungsten

electrode with a continuously fed electrode wire. One of

the basic changes that made the process more usable was

the small-diameter electrode wires and the

constant-voltage poser source. This principle had been

patented earlier by H.E. Kennedy. The initial

introduction of GMAW was for welding nonferrous metals.

The high deposition rate led users to try the process on

steel. The cost of inert gas was relatively high and the

cost savings were not immediately available.

ALLCHORN

MARITIME LTD - This is a community interest company that acquired

the Allchorn

boats that offered coastal cruises from Eastbourne Pier to the

Lighthouse and back. The new owners of the hulls are hoping to restore

these fine wooden built vessels to full working order. Copyright photograph © 5 December 2016. You will need the permission of

Bluebird Marine Systems to use this photograph except for research,

educational or media review purposes.

1950

In 1953, Lyubavskii and Novoshilov announced the use of

welding with consumable electrodes in an atmosphere of

CO2 gas. The CO2 welding process immediately gained

favor since it utilized equipment developed for inert

gas metal arc welding, but could now be used for

economically welding steels. The CO2 arc is a hot arc

and the larger electrode wires required fairly high

currents. The process became widely used with the

introduction of smaller-diameter electrode wires and

refined power supplies. This development was the

short-circuit arc variation which was known as

Micro-wire®, short-arc, and dip transfer welding, all

of which appeared late in 1958 and early in 1959. This

variation allowed all-position welding on thin materials

and soon became the most popular of the gas metal arc

welding process variations.

1960

Another variation was the use of inert gas with small

amounts of oxygen that provided the spray-type arc

transfer. It became popular in the early 1960s. A recent

variation is the use of pulsed current. The current is

switched from a high to a low value at a rate of once or

twice the line frequency.

Soon after the introduction of CO2 welding, a variation

utilizing a special electrode wire was developed. This

wire, described as an inside-outside electrode, was

tubular in cross section with the fluxing agents on the

inside. The process was called Dualshield®, which

indicated that external shielding gas was utilized, as

well as the gas produced by the flux in the core of the

wire, for arc shielding. This process, invented by

Bernard, was announced in 1954, but was patented in

1957, when the National Cylinder Gas Company

reintroduced it.

In 1959, an inside-outside electrode was produced which

did not require external gas shielding. The absence of

shielding gas gave the process popularity for

noncritical work. This process was named Innershield®.

The electroslag welding process was announced by the

Soviets at the Brussels World Fair in Belgium in 1958.

It had been used in the Soviet Union since 1951, but was

based on work done in the United States by R.K. Hopkins,

who was granted patents in 1940. The Hopkins process was

never used to a very great degree for joining. The

process was perfected and equipment was developed at the

Paton Institute Laboratory in Kiev, Ukraine, and also at

the Welding Research Laboratory in Bratislava,

Czechoslovakia. The first production use in the U.S. was

at the Electromotive Division of General Motors

Corporation in Chicago, where it was called the

Electro-molding process. It was announced in December

1959 for the fabrication of welded diesel engine blocks.

The process and its variation, using a consumable guide

tube, is used for welding thicker materials.

The Arcos Corporation introduced another vertical

welding method, called Electrogas, in 1961. It utilized

equipment developed for electroslag welding, but

employed a flux-cored electrode wire and an externally

supplied gas shield. It is an open arc process since a

slag bath is not involved. A newer development uses

self-shielding electrode wires and a variation uses

solid wire but with gas shielding. These methods allow

the welding of thinner materials than can be welded with

the electroslag process.

Robert M. Gage invented plasma arc welding in 1957. This

process uses a constricted arc or an arc through an

orifice, which creates an arc plasma that has a higher

temperature than the tungsten arc. It is also used for

metal spraying and for cutting.

The electron beam welding process, which uses a focused

beam of electrons as a heat source in a vacuum chamber,

was developed in France. J.A. Stohr of the French

Atomic

Energy Commission mad the first public disclosure of the

process on November 23, 1957. In the United States, the

automotive and aircraft engine industries are the major

users of electron beam welding.

FABRICATION

- "Welding

is an essential skill for fabricators, without it we would be back in

the riveting dark ages - and dependent on nuts and bolts. There is

nothing wrong with rivets and bolting structures together, but it is not

so strong as a fixing that is as strong as the parent metal to the point

where a join can be almost as good as a continuous run of metal."

Here you see an experienced welder/fabricator preparing a steel

weld with an

angle grinder. Nelson

is also a boat builder when not messing about with cars.

Copyright photographs © 5 July 2004. You will need the

permission of Blueplanet Universal Holdings Ltd to use

these photographs legally.

Most Recent

Friction welding, which uses rotational speed and upset

pressure to provide friction heat, was developed in the

Soviet Union. It is a specialized process and has

applications only where a sufficient volume of similar

parts is to be welded because of the initial expense for

equipment and tooling. This process is called inertia

welding.

Laser welding is one of the newest processes. The laser

was originally developed at the Bell Telephone

Laboratories as a communications device. Because of the

tremendous concentration of energy in a small space, it

proved to be a powerful heat source. It has been used

for cutting metals and nonmetals. Continuous pulse

equipment is available. The laser is finding welding

applications in automotive metalworking operations.

WELDING

KIT - In our opinion this has

got to be the Rolls-Royce of welding equipment. This is one of the

welders from the R-Tech range that is extremely versatile. It is a

digital DC welder that is inverter based. It is also one of the few

machines that you can buy that allows the operator to use a 'spool on

gun,' where instead of using the drum inside the machine feeding through

a euro-torch, you can use a gun that has a 0.5kg wire drum spool holder

and drive mechanism mounted on the torch. This is ideal for aluminium

welding where the friction of the euro-torch liner is often enough to

prevent the pinch wheels from being able to deliver wire to the welding

tip. The MTS255S Digital Synergic Inverter MIG, DC TIG and MMA welder features a high 35% duty cycle, Synergic digital control panel with 9 memory store facility, MIG wave adjustment for fine control of welding arc, 5KG reel capacity with optional spool gun system for easy alloy welding. Ideal for maintenance, automotive and fabrication welding.

This machine automatically adjusts wire feed to power/wire type set by operator. It has infinite fine control of welding voltage/amperage to offer very smooth low splatter welds on all

steels and

aluminium due to its inverter technology. The metal wire feed takes 0.6, 0.8 and 1.0mm wire. This

beautiful machine outputs:

250 Amp MIG Welder, 250 Amp DC TIG Welder and 200 Amp Arc/MMA Welder. You

can weld from as low as 25 Amps in MIG mode. The machine is generator Friendly (min rating 10KVA)

and takes

5kg reels of MIG Wire.

CONTACT:

R-Tech Welding Equipment

Limited, Unit G1 & G2 Innsworth Technology Park,

Innsworth Lane, Gloucester, GL3 1DL. Telephone: 01452 733933. Website: http://www.r-techwelding.co.uk/

Copyright photograph © 5 December 2016. You will need the

permission of Bluebird Marine Systems to use this photograph except for

research, educational or media review purposes.

|

|

Welding

& joining technology

TWI

has expertise in all forms of welding,

surfacing, cutting and other joining

methods for metals,

plastics,

composites

and ceramics,

and in the properties of joints. Find out

for yourself using our technology

file and JoinIT®

|

|

|

|

|

Materials

engineering

Corrosion,

cutting,

design

& structural integrity, environment,

joining ( adhesive

bonding, arc

welding, brazing,

electron

beam welding, friction

welding, laser

welding, oxy-fuel

welding, soldering and much more), fatigue,

fracture, manufacturing,

materials

weldability, NDT/NDE,

quality,

surface

engineering.

|

|

|

|

|

Industry

support

TWI

works with industry by supplying

technologies and services that grow

business, reduce costs, improve safety,

manage risk and improve efficiency in aerospace,

construction,

defence,

electronics

& sensors, medical,

off-highway,

oil,

gas & chemical, power,

rail,

road

transport and shipbuilding.

TWI also offers services in asset

management, risk

assessment, corrosion,

surface

engineering, metallurgy,

finite

element analysis, NDT,

plastics

welding, health

and safety, and manufacturing.

|

|

|

|

|

Membership

benefits for companies and individuals

Industrial

Membership

gives companies access to

all TWI's facilities and expertise,

including consultancy,

research,

and information

services (including Weldasearch)

and exclusive parts of JoinIT®.

The

Welding Institute is the UK

professional organisation for welding

engineers. Professional membership offers

many opportunities for professional

development, whilst the Welding

and Joining Society is open to all.

|

|

|

|

|

Problem

solving & exploiting innovation

TWI

carries out confidential Single

Client and Group/Joint

Industry Projects. Members also fund a

Core

Research Programme. EC agencies such

as ERDF and ESF in association with UK

Government Offices and Regional

Development Agencies sponsor Regional

Projects. TWI also forms Collaborative

Projects with joint industrial and

European sponsorship.

|

|

|

|

|

Training

& certification

TWI

runs training

courses and examinations

worldwide. In the UK there are courses on welding

technology, practical

welding, non-destructive testing,

materials performance, materials joining, plastics,

and microelectronics.

Many of these lead to internationally-recognised

qualifications, including CSWIP,

ASNT,

PCN,

BGAS,

EWF/IIW.

Company

Certification is also available.

|

|

|

|

|

Software

TWI

offers software

for sale: Weldspec

(welding procedures), Welderqual

(welder certification), NDTspec

(NDE reports), Welding

Co-ordinator (production welds), RISKWISE

(plant risk assessment), Crackwise

(defect assessment), and multi-media

training software.

|

|

|

|

|

TWI

locations

TWI's

main site is at Granta

Park, Cambridge, UK. It has UK

Regional Technology Centres at

Middlesbrough for the North

East, Sheffield for Yorkshire

and Humber, and Port

Talbot for Wales. There is also a

Training and Qualification Centre at Kuala

Lumpur, Malaysia, and there are agents

around the world.

|

|

|