|

HOW

CAN A BOAT

BENEFIT FROM WIND TURBINES ?

Bluefish Robot Boat Front Elevation

2013 |

You

can see from the drawing above that the Bluefish ZCC (Bluebird Marine Systems

Ltd) has four mini wind

turbines, each of which generates 1.5Kw to provide enough energy

to run the integrated autonomous hardware. With research projects such as

this, the equipment is bulky and relatively energy hungry, but with each

refinement the controlling chips, software and mechanical end effectors become

smaller and more efficient. SolarNavigator

was the first (proposed) autonomous vessel to harness wind energy in this way,

but the Bluefish ZCC development programme (again a proposed development of

GB1301488) has taken this a stage further with up to 40kW wind turbines

onboard for a civilian vessel and 80kW for military variants. You can

read more about how the system works on their pages by clicking on the

pictures above and below.

Bluefish

Robot Boat

sporting 2 x 20kW wind turbines

and the ability to raise and lower the turbines into and out of the airstream

- as conditions dictate.

WIND

TURBINES

A wind turbine is a machine that converts the kinetic energy in wind into mechanical energy. If the mechanical energy is used directly by machinery, such as a pump or grinding stones, the machine is usually called a windmill. If the mechanical energy

is converted to electricity, the machine is called a wind generator,

or more commonly a wind turbine (wind energy converter WEC).

A

wind turbine is old technology applied to meet new challenges. We need

to adapt and use every means at our disposal to combat global warming

and carbon dioxide build up, yet

still provide energy for our modern (lavish)

lifestyles. Whatever your views as to the use of alternative energy,

as an engineering student you will probably want to know how these

beautiful machines work. I know I have always been fascinated by them.

NK NEW

EU DIRECTIVES MARCH 21 2013 - sea planning law to boost investment

If planned without cross-border cooperation, grid investments risk being less effective.

EU Member States will have to plan the use of their sea space and work together where they share a sea basin, according to a proposed European Commission Directive on maritime spatial planning and integrated coastal management. The Directive will also facilitate the creation of a transnational European offshore electricity grid by encouraging Member States to map areas for electricity infrastructure at sea. If planned without cross-border cooperation, grid investments risk being less effective. The Offshore Grid project calculated that by clustering wind farms in hubs which could cross borders, around €14bn could be saved compared to connecting wind farms individually to the shore. "The European Wind

Energy Association strongly supports the Commission's proposal, which will allow the European offshore wind energy sector to plan investments based on a mapped use of sea space, creating growth and jobs in the maritime sector," said Anne-Bénédicte Genachte, offshore regulatory affairs advisor for the European Wind Energy Association

(EWEA). "The ball is now in the hands of the European Parliament and Member States, and unfortunately some big Member States are already voicing opposition. We hope that governments will understand the importance of having an EU planning framework for the growth of the maritime economy and we hope to count on Parliament in order to get the directive adopted before the European elections in 2014." In 2012 offshore wind totalled 5 GW in the EU and this is projected to rise to 40 GW, employing 170,000 people by 2020, and to 150 GW employing 300,000 people by 2030. Offshore wind energy is often caught between conflicting uses and rules from different sectors which can create project uncertainty and delays, impairing the sector's potential for growth. These are risks that could rise without effective maritime spatial planning as offshore wind energy grows. The Directive should benefit the entire maritime economy by helping Member States to achieve well planned use of the sea for activities such as energy, transport, fisheries, leisure and environmental protection.

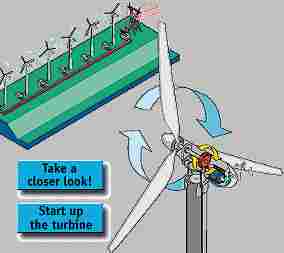

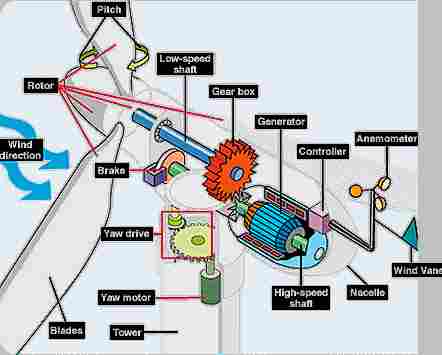

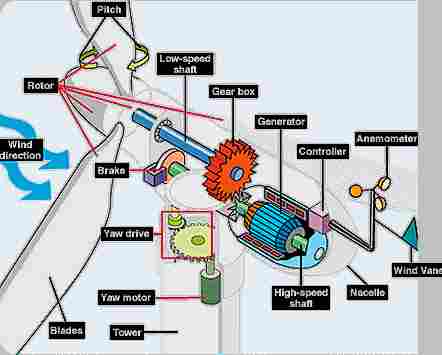

Find

Out How the Turbine Works

This aerial

view of a wind power plant shows how a group of wind turbines can make

electricity for the utility grid. The electricity is sent through transmission

and distribution lines to homes, businesses, schools, and so on.

These

three-bladed wind turbines are operated "upwind," with the blades

facing into the wind. The other common wind turbine type is the two-bladed,

downwind turbine.

So how do

wind turbines make electricity? Simply stated, a wind turbine works the

opposite of a fan. Instead of using electricity to make wind, like a fan, wind

turbines use wind to make electricity. The wind turns the blades, which spin a

shaft, which connects to a generator and makes electricity. Utility-scale

turbines range in size from 50 to 750 kilowatts. Single small turbines, below

50 kilowatts, are used for homes, telecommunications dishes, or

water pumping.

Look

at the Wind Turbine Close Up

Wind turbines can be separated into two types based on the axis about which the turbine rotates. Turbines that rotate around a horizontal axis are more common. Vertical-axis turbines are less frequently used.

Wind turbines can also be classified by the location in which they are to be used. Onshore, offshore, or even aerial wind turbines have unique design

characteristics.

Wind turbines may also be used in conjunction with a solar collector to extract the energy due to air heated by the Sun and rising through a large vertical solar updraft tower.

Horizontal axis

Horizontal-axis wind turbines (HAWT) have the main rotor shaft and electrical generator at the top of a tower, and must be pointed into the wind. Small turbines are pointed by a simple wind vane, while large turbines generally use a wind sensor coupled with a servo motor. Most have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable for

generating electricity.

Since a tower produces turbulence behind it, the turbine is usually pointed upwind of the tower. Turbine blades are made stiff to prevent the blades from being pushed into the tower by high winds. Additionally, the blades are placed a considerable distance in front of the tower and are sometimes tilted up a small amount.

Downwind machines have been built, despite the problem of turbulence, because they don't need an additional mechanism for keeping them in line with the wind, and because in high winds, the blades can be allowed to bend which reduces their swept area and thus their wind resistance. Because turbulence leads to fatigue failures and reliability is so important, most HAWTs are upwind machines.

Doesburger windmill, Ede, The

Netherlands

There are several types of HAWT:

These four- (or more) bladed squat structures, usually with wooden shutters or fabric sails, were developed in Europe. These windmills were pointed into the wind manually or via a tail-fan and were typically used to grind grain. In the Netherlands they were also used to pump water from low-lying land, and were instrumental in keeping its polders dry. Windmills were also located throughout the USA, especially in the Northeastern region.

Modern Rural Windmills

These windmills, invented in 1876 by Griffiths Bros and Co (Australia), were used by Australian and later American farmers to pump water and to generate electricity. They typically had many blades, operated at tip speed ratios (defined below) not better than one, and had good starting torque. Some had small direct-current generators used to charge storage batteries, to provide a few lights, or to operate a radio receiver. The American rural electrification connected many farms to centrally-generated power and replaced individual windmills as a primary source of farm power in the 1950's. Such devices are still used in locations where it is too costly to bring in commercial power.

Wind turbines near Aalborg, Denmark

A standard doorway can be seen at the base of the

pylon for scale

Common modern wind turbines

Usually three-bladed, sometimes two-bladed or even one-bladed (and counterbalanced), and pointed into the wind by computer-controlled motors. The rugged three-bladed turbine type has been championed by Danish turbine manufacturers. These have high tip speeds of up to 6x wind speed, high efficiency, and low torque ripple which contributes to good reliability. This is the type of turbine that is used commercially to produce electricity. The blades are usually colored light gray to blend in with the clouds and range in length from 20 to 40 metres (60 to 120 feet) or more.

Cyclic stresses and vibration

Cyclic stresses fatigue the blade, axle and bearing material, and were a major cause of turbine failure for many years. Because wind velocity often increases at higher altitudes, the backward force and torque on a horizontal-axis wind turbine

(HAWT) blade peaks as it turns through the highest point in its circle. The tower hinders the airflow at the lowest point in the circle, which produces a local dip in force and torque. These effects produce a cyclic twist on the main bearings of a

HAWT. The combined twist is worst in machines with an even number of blades, where one is straight up when another is straight down. To improve reliability, teetering hubs have been used which allow the main shaft to rock through a few degrees, so that the main bearings do not have to resist the torque peaks.

When the turbine turns to face the wind, the rotating blades act like a gyroscope. As it pivots, gyroscopic precession tries to twist the turbine into a forward or backward somersault. For each blade on a wind generator's turbine, precessive force is at a minimum when the blade is horizontal and at a maximum when the blade is vertical. This cyclic twisting can quickly fatigue and crack the blade roots, hub and axle of the turbine.

Vertical axis

12 m Windmill with rotational sails in the Osijek CroatiaVertical-axis wind turbines (or

VAWTs) have the main rotor shaft running vertically. Key advantages of this arrangement are that the generator and/or gearbox can be placed at the bottom, near the ground, so the tower doesn't need to support it, and that the turbine doesn't need to be pointed into the wind. Drawbacks are usually pulsating torque that can be produced during each revolution and drag created when the blade rotates into the wind. It is also difficult to mount vertical-axis turbines on towers, meaning they must operate in the often slower, more turbulent air flow near the ground, resulting in lower energy extraction efficiency.

Windmill with rotational sails

This is a new invention. This windmillstarts making electricity above a windspeed of 2m/s. Its sails contract and expand as the wind speed changes. This windmill has three sails of variable surface area. The speed is controlled through a magnetic rev counter that expands or contracts the sails according to

windspeed. A (microprocessor type) control unit controls the sails either manually or automatically. In case of a control unit failure, strong winds would tear the sails, but the frame would remain intact.

Neo-AeroDynamic

This has an airfoil base designed to harness the kinetic energy of the fluid flow via an artificial current around its center. It is differentiated from others by its capability to unitize most of the air mass passing through redirecting it to flow over the upper chamber of the airfoils, and causing a lift force all around. It is applicable not only to wind, but also to a variety of hydroelectric applications, including free-flow (rivers, creeks), tidal, oceanic currents and wave motion, via ocean wave surface currents. Views of Hydro model, :Portable aero model

30 m Darrieus wind turbine in the Magdalen Islands

Darrieus wind turbine

"Eggbeater" turbines. They have good efficiency, but produce large torque ripple and cyclic stress on the tower, which contributes to poor reliability. Also, they generally require some external power source, or an additional Savonius rotor, to start turning, because the starting torque is very low. The torque ripple is reduced by using 3 or more blades which results in a higher solidity for the rotor. Solidity is measured by blade area over the rotor area. Newer Darrieus type turbines are not held up by guy wires but have an external superstructure connected to the top bearing.

Giromill

A type of Darrieus turbine, these lift-type devices have vertical blades. The cycloturbine variety have variable pitch to reduce the torque pulsation and are self-starting [1]. The advantages of variable pitch are: high starting torque; a wide, relatively flat torque curve; a lower blade speed ratio; a higher coefficient of performance; more efficient operation in turbulent winds; and a lower blade speed ratio which lowers blade bending stresses. Straight, V, or curved blades may be used.

Savonius wind turbine

These are drag-type devices with two- (or more) scoops that are used in anemometers, the Flettner vents (commonly seen on bus and van roofs), and in some high-reliability low-efficiency power turbines. They always self-starting if there are at least three scoops. They sometimes have long helical scoops to give a smooth torque. The Banesh rotor and especially the Rahai rotor improve efficiency with blades shaped to produce significant lift as well as drag.

Windstar turbines

These lift-type devices made by Wind Harvest have straight, extruded aluminum blades attached at each end to a central rotating shaft and are operated as Linear Array Vortex Turbine Systems

(LAVTS). Vertical-axis rotors each with their own 50-75kW generator are placed in three to any number of rotors in linear arrays with each rotor’s blades passing within two feet of its neighbor. In this configuration, the center rotors gain an increase in output and efficiency (reaching the high efficiencies of

HAWTs). This increased efficiency is protected under patent (number 6784566) as the "vortex effect". Each rotor unit has a dual braking system of pneumatic disc brakes and blade pitch. The newest Windstar LAVTS stand 50 feet tall, have 1500 and 3000 square feet of swept area per rotor and are designed to be placed in the turbulent winds within the understory of wind farms.

Wind

turbine tour

Offshore

Offshore wind turbines near CopenhagenOffshore wind development zones are generally considered to be ten kilometers or more from land. Offshore wind turbines are less obtrusive than turbines on land, as their apparent size and noise can be mitigated by distance. Because water has less surface roughness than land (especially deeper water), the average wind speed is usually considerably higher over open water. Capacity factors

(utilisation rates) are considerably higher than for onshore and near-shore locations which allows offshore turbines to use shorter towers, making them less visible.

In stormy areas with extended shallow continental shelves (such as Denmark), turbines are practical to install — Denmark's wind generation provides about 25-30% of total electricity demand in the country, with many offshore

windfarms. Denmark plans to increase wind energy's contribution to as much as half of its electrical supply.

Locations have begun to be developed in the North American Great Lakes - with one project by Trillium Power approximately 20 km from shore and over 700 MW in size. Ontario, Canada is aggressively pursuing wind power development and has many onshore wind farms and several proposed near-shore locations but presently only one offshore development.

In most cases offshore environment is more expensive than onshore. Offshore towers are generally taller than onshore towers once the submerged height is included, and offshore foundations are more difficult to build and more expensive. Power transmission from offshore turbines is generally through undersea cable, which is more expensive to install than cables on land, and may use high voltage direct current operation if significant distance is to be covered — which then requires yet more equipment. The offshore environment can also be corrosive and abrasive in salt water locations but locations such as the Great Lakes are in fresh water and do not have many of the issues found in the ocean or sea. Repairs and maintenance are usually much more difficult, and generally more costly, than on onshore turbines. Offshore wind turbines are outfitted with extensive corrosion protection measures like coatings and cathodic protection however some of these measures may not be required in fresh water locations.

While there is a significant market for small land-based windmills, offshore wind turbines have recently been and will probably continue to be the largest wind turbines in operation, because larger turbines allow for the spread of the high fixed costs involved in offshore operation over a greater quantity of generation, reducing the average cost. For similar reasons, offshore wind farms tend to be quite large—often involving over 100 turbines—as opposed to onshore wind farms which can operate competitively even with much smaller installations.

There are some conceptual designs that might make use of the unique offshore environment. For example, a floating turbine might orient itself downwind of its anchor, and thus avoid the need for a yawing mechanism. One concept for offshore turbines has them generate rain, instead of electricity. The turbines would create a fine aerosol, which is envisioned to increase evaporation and induce rainfall, hopefully on

land.

Near-shore

Near-shore turbines are generally considered to be within a zone that is on land three kilometers of a shoreline and on water within ten kilometers of land. Wind speeds in these zones share wind speed characteristics of both onshore wind and offshore wind. Issues that are shared within near-shore wind development zones are ornithological (including bird migration and nesting), aquatic habitat, transportation (including shipping and boating) and visual aesthetics.

Sea shores also tend to be windy areas and good sites for turbine installation, because a primary source of wind is convection from the differential heating and cooling of land and sea over the course of day and night. Winds at sea level carry somewhat more energy than winds of the same speed in mountainous areas because the air at sea level is denser.

Near-shore wind farm siting can sometimes be highly controversial as coastal sites are often picturesque and environmentally sensitive (for instance, having substantial bird life).

Onshore

Wind turbines near Walla Walla in WashingtonOnshore turbine installations in hilly or mountainous regions tend to be on ridgelines generally three kilometers or more inland from the nearest shoreline. This is done to exploit the topographic acceleration where the hill or ridge causes the wind to accelerate as it is forced over it. The additional wind speeds gained in this way make large differences to the amount of energy that is produced. Great attention must be paid to the exact positions of the turbines (a process known as

micro-siting) because a difference of 30 m can sometimes mean a doubling in output. Local winds are often monitored for a year or more with anemometers and detailed wind maps constructed before wind generators are installed.

For smaller installations where such data collection is too expensive or time consuming, the normal way of prospecting for wind-power sites is to directly look for trees or vegetation that are permanently "cast" or deformed by the prevailing winds. Another way is to use a wind-speed survey map, or historical data from a nearby meteorological station, although these methods are less reliable.

Wind farm siting can sometimes be controversial, particularly as the hilltop, often coastal sites preferred are often picturesque and environmentally sensitive (for instance, having substantial bird life). Local residents in a number of potential sites have strongly opposed the installation of wind farms, and political support has resulted in the blocking of construction of some

installations.

Turbine

blade at Southampton docks - Nelson Kruschandl in foreground

Turbine design and construction

Advantages of vertical wind turbines

Easier to maintain because most of their moving parts are located near the ground. This is due to the vertical wind turbine’s shape. The airfoils or rotor blades are connected by arms to a shaft that sits on a bearing and drives a generator below, usually by first connecting to a gearbox.

As the rotor blades are vertical, a yaw device is not needed, reducing the need for this bearing and its cost.

Vertical wind turbines have a higher airfoil pitch angle, giving improved aerodynamics while decreasing drag at low and high pressures.

Mesas, hilltops, ridgelines and passes can have higher and more powerful winds near the ground than up high because of the speed up effect of winds moving up a slope or funneling into a pass combining with the winds moving directly into the site. In these places, VAWTs placed close to the ground can produce more power than HAWTs placed higher up.

Low height useful where laws do not permit structures to be placed high.

Smaller VAWTs can be much easier to transport and install.

Does not need a free standing tower so is much less expensive and stronger in high winds that are close to the ground.

Usually have a lower Tip-Speed ratio so less likely to break in high winds.

Disadvantages of vertical wind turbines

Most VAWTs produce energy at only 50% of the efficiency of HAWTs in large part because of the additional drag that they have as their blades rotate into the wind. This can be overcome by using structures to funnel more and align the wind into the rotor (e.g. "stators" on early Windstar turbines) or the "vortex" effect of placing straight bladed VAWTs closely together (e.g. Patent # 6784566).

There may be a height limitation to how tall a vertical wind turbine can be built and how much sweep area it can have.

Most VAWTS need to be installed on a relatively flat piece of land and some sites could be too steep for them but are still usable by

HAWTs.

Most VAWTs have low starting torque.

A VAWT that uses guyed wires to hold it in place puts stress on the bottom bearing as all the weight of the rotor is on the bearing. Guyed wires attached to the top bearing increase downward thrust in wind gusts. Solving this problem requires a superstructure to hold a top bearing in place to eliminate the downward thrusts of gust events in guyed wired models.

Wind

turbines in Southern California

Advantages of horizontal wind turbines

Blades are to the side of the turbine's center of gravity, helping stability.

Ability to wing warp, which gives the turbine blades the best angle of attack. Allowing the angle of attack to be remotely adjusted gives greater control, so the turbine collects the maximum amount of wind energy for the time of day and season.

Ability to pitch the rotor blades in a storm, to minimize damage.

Tall tower allows access to stronger wind in sites with wind shear. In some wind shear sites, every ten meters up, the wind speed can increase by 20% and the power output by 34%.

Tall tower allows placement on uneven land or in offshore locations.

Can be sited in forests above the treeline.

Most are self-starting.

Can be cheaper because of higher production volume, larger sizes and, in general higher capacity factors and efficiencies.

Disadvantages of horizontal wind turbines

HAWTs have difficulty operating in near ground, turbulent winds because their yaw and blade bearing need smoother, more laminar wind flows.

The tall towers and long blades (up to 180 feet long) are difficult to transport on the sea and on land. Transportation can now cost 20% of equipment costs.

Tall HAWTs are difficult to install, needing very tall and expensive cranes and skilled operators.

Supply of HAWTs is less than demand and between 2004 and 2006, turbine prices increased up to 60%. At the end of 2006, all major manufacturers were booked up with orders through 2008.

The FAA has raised concerns about tall HAWTs effects on radar in proximity to air force bases.

Their height can create local opposition based on impacts to viewsheds.

Offshore towers can be a navigation problem and must be installed in shallow seas. HAWTs can't be floated on barges.

Downwind variants suffer from fatigue and structural failure caused by turbulence.

Horizontal-axis wind turbine aerodynamics

The aerodynamics of a horizontal-axis wind turbine are complex. The air flow at the blades is not the same as the airflow far away from the turbine. The very nature of the way in which energy is extracted from the air also causes air to be deflected by the turbine. In addition, the aerodynamics of a wind turbine at the rotor surface include effects that are rarely seen in other aerodynamic fields.

Special wind turbines

One E-66 wind turbine at Windpark Holtriem, Germany carries an observation deck, open for visitors to see. Another turbine of the same type, with an observation deck, can be located in

Swaffham, England.

A series of floating wind turbines utilizing the Magnus Effect are in development in Canada by Magenn Power. They deliver power to the ground by a tether system.

Wind

turbine

overload fire

History

The world's first megawatt wind turbine on Grandpa's Knob, Castleton, VermontWind machines were used for grinding grain in Persia as early as 200 B.C. This type of machine was introduced into the Roman Empire by 250 A.D. By the 14th century Dutch windmills were in use to drain areas of the Rhine River delta. In

Denmark by 1900 there were about 2500 windmills for mechanical loads such as pumps and mills, producing an estimated combined peak power of about 30 MW. The first windmill for electricity production was built in Cleveland, Ohio by Charles F Brush in 1888, and in 1908 there were 72 wind-driven electric generators from 5 kW to 25 kW. The largest machines were on 24 m (79 ft) towers with four-bladed 23 m (75 ft) diameter rotors.

By the 1930s windmills were mainly used to generate electricity on farms, mostly in the United States where distribution systems had not yet been installed. In this period, high-tensile steel was cheap, and windmills were placed atop prefabricated open steel lattice towers. A forerunner of modern horizontal-axis wind generators was in service at Yalta, USSR in 1931. This was a 100 kW generator on a 30 m (100 ft) tower, connected to the local 6.3 kV distribution system. It was reported to have an annual load factor of 32 per cent, not much different from current wind machines.

Records

The world's largest turbines are manufactured by the Northern German companies Enercon and

REpower. The Enercon E112 delivers up to 6 MW , has an overall height of 186 m (610 ft) and a diameter of 114 m (374 ft). The REpower 5M delivers up to 5 MW , has an overall height of 183 m (600 ft) and a diameter of 126 m (413 ft).

The turbine closest to the

North Pole is a Nordex N-80 in Havoygalven near

Hammerfest, Norway. The ones closest to the South Pole are two Enercon E-30 in Antarctica, used to power the

Australian Research Division's Mawson

Station.

Offshore

wind farm off Danish coast

Wind

Turbine Glossary

Anemometer:

Measures the wind speed and transmits wind speed data to the controller.

Blades:

Most turbines have either two or three blades. Wind blowing over the blades

causes the blades to "lift" and rotate.

Brake:

A disc brake which can be applied mechanically, electrically, or hydraulically

to stop the rotor in emergencies.

Controller:

The controller starts up the machine at wind speeds of about 8 to 16 miles per

hour (mph) and shuts off the machine at about 65 mph. Turbines cannot operate

at wind speeds above about 65 mph because their generators could overheat.

Gear

box: Gears connect the low-speed shaft to

the high-speed shaft and increase the rotational speeds from about 30 to 60

rotations per minute (rpm) to about 1200 to 1500 rpm, the rotational speed

required by most generators to produce electricity. The gear box is a costly

(and heavy) part of the wind turbine and engineers are exploring

"direct-drive" generators that operate at lower rotational speeds

and don't need gear boxes.

Generator:

Usually an off-the-shelf induction generator that produces 60-cycle AC

electricity.

High-speed

shaft: Drives the generator.

Low-speed

shaft: The rotor turns the low-speed

shaft at about 30 to 60 rotations per minute.

Nacelle:

The rotor attaches to the nacelle, which sits atop the tower and includes the

gear box, low- and high-speed shafts, generator, controller, and brake. A

cover protects the components inside the nacelle. Some nacelles are large

enough for a technician to stand inside while working.

Pitch:

Blades are turned, or pitched, out of the wind to keep the rotor from turning

in winds that are too high or too low to produce electricity.

Rotor:

The blades and the hub together are called the rotor.

Tower:

Towers are made from tubular steel (shown here) or steel lattice. Because wind

speed increases with height, taller towers enable turbines to capture more

energy and generate more electricity.

Wind

direction: This is an "upwind"

turbine, so-called because it operates facing into the wind. Other turbines

are designed to run "downwind", facing away from the wind.

Wind

vane:

Measures wind direction and communicates with the yaw drive to orient the

turbine properly with respect to the wind.

Yaw

drive: Upwind turbines face into the

wind; the yaw drive is used to keep the rotor facing into the wind as the wind

direction changes. Downwind turbines don't require a yaw drive, the wind blows

the rotor downwind.

Yaw

motor: Powers the yaw drive.

Small-scale wind power in Marshall County, Indiana

|

Links to

Other Web Sites on Wind Energy

|

Wind Turbine Manufacturers

Borupvej 16 - DK-7330 Brande

Tel : +45 9942 2222

Fax : +45 9999 2222

E-mail : bonus@bonus.dk

Turbine sizes: 600 kW, 1000 kW, 1300 kW, 2000 kW, 2300 kW

Alsvej 21 - DK-8900 Randers

Tel : +45 8710 5000 - Fax : +45 8710 5001

E-mail : mail@neg-micon.dk

Turbine sizes: 750 kW, 900 kW, 1000 kW, 1500 kW, 2000 kW, 2500 kW, 2750 kW

Svindbaek - DK-7323 Give

Tel : +45 7573 4400 - Fax : +45 7573 4147

E-mail : nordex@nordex.dk

Turbine sizes: 600kW, 800kW, 1300 kW, 2300 kW, 2500 kW

Smed Sørensens Vej 5 - DK-6950

Ringkøbing, Denmark

Tel : +45 9675 2575 - Fax : +45 9675 2436

E-mail : vestas@vestas.dk

Turbine sizes: 660 kW, 850 kW, 1750 kW, 1800 kW, 2000 kW, 3000 kW

Rotor Blade Manufacturers

Major Component and Service

Suppliers

Other Wind Energy Associations

|

Wind Energy Research

Institutions

Other Research Institutions

University Courses in Wind

Energy

Governmental Institutions

KEMA

(in Dutch) Turbine installation data for the Netherlands.

Suivi-eolien about wind energy

production and development in France (in English and French)

Horns

Rev (DK)

160 MW offshore wind farm under construction in the North Sea.

WindStats

Newsletter

Articles plus loads of statistics on wind energy production

in many parts of the world.

Yes2wind

A cooperation between WWF, Greenpeace and Friends of the Earth.

We maintain only a selected

links linking other wind energy associations, research institutions

and other nonprofit institutions or media with web sites with substantial

wind energy coverage.

|

|

Wind Energy Reference Manual

|

|

Wind

Energy Concepts

Unit

Abbreviations

Wind

Speeds

Wind

Speed Scale

Roughness

Classes and Roughness Lengths

Roughness

Class Calculator

Roughness

Classes and Roughness Length Table

Density

of Air at Standard Atmospheric Pressure

Viscosity

of air

Power

of the Wind

Standard

Wind Class Definitions (Used in the U.S.)

Energy

and Power Definitions

Wind

Energy Glossary

Energy

Energy

Units

Power

Power

Units

|

Proof

of Betz' Law

Wind

Energy Acoustics

dB(A)

Sound Levels in decibels and Sound Power in W/m 2

Sound

Level by Distance from Source

Adding

Sound Levels from Two Sources

How

to add sound levels in general

Wind

Energy and Electricity

Three

Phase Alternating Current

Connecting

to Three Phase Alternating Current

Electromagnetism

Part 1

Electromagnetism

Part 2

Induction

Part 1

Induction

Part 2

Wind

Energy, Environment, and Fuels

Energy

Content of Fuels

CO

2 -Emissions from Fuels

Bibliography

|

Build

your own wind turbine

MORE USEFUL

LINKS

-

BBC

News,"Wind farms 'must take root in UK", http://news.bbc.co.uk/2/hi/science/nature/4560139.stm

-

http://telosnet.com/wind/early.html

-

Listing

of wind technology websites at the Open Directory Project

-

Eric,

Eggleston, What are Vertical-Axis Wind Turbines (VAWTS)?, American

Wind Energy Association, Copyright 1998

-

History

of Wind Energy, U.S Department of Energy, Copyright 1997-2005

-

How

Wind Turbines Work, U.S Department of Energy, Copyright 1997-2005

-

What

are the Basic Wind Turbine Configurations?, American Wind,

Copyright 1998, 11/2/05

-

Wind

Energy Economics, Danish Wind Industry Association ,Copyright

1997-2003

-

Wind

Energy Technology Website of the World Wind Energy Association

-

Wind

Turbine Simulation, National Geographic

-

How

to build a wind turbine at home for $150

-

Wind

turbines and birds

ENERGY

GENERATING-DISTRIBUTION UTILITIES

When

a pirate whaler kills a small humpback whale, a larger whale sinks the

pirate ship to avenge the death, but is itself wounded. The pirates

put a price on the whale's head, but an adventurer in an advanced

solar powered boat races to beat the pirates and save the wounded

animal.

This

modern adventure story by Jameson Hunter is due to be

released late 2013

as an e-book

|