|

DRAGONFLY:

THE AUTONOMOUS ZERO CARBON MINE HUNTER

Modern

mines present a serious danger to the safe operation of naval

ships and submarines in particular, especially in times of war,

though, it is prudent in

peacetime to know where an enemy might place mines. For this reason

persistent countermeasures are essential so that should war break out, the

decks are clear for action, inasmuch as allies would know beforehand where

a danger area was and could eliminate it straight away. If a potential enemy knows that an opposing force has

such technology, they are less likely to want to go to war. Dragonfly is

therefore a powerful weapon in the peace keepers armoury.

The

problem for navies in peacetime, is

being able to constantly monitor potential threats where budgetary constraints exist,

and defence review

is forcing cutbacks, and now there is a requirement to cut emissions. In the case of Dragonfly, once the

initial purchase is made, there are no fuel or crew provisioning costs,

simply because the ship derives all of it's propulsive and operational

energy requirements from nature. It is a zero carbon vessel.

A unique,

patent blend of solar and wind energy harvesting devices, allows Dragonfly class ships to cruise continuously at between

7-10 knots with a maximum

speed of 18 knots, mopping up the oceans as they go. The SNAV/Bluefish platform is currently under development

in the United Kingdom, with 3 small scale hulls now in production to test various

robotic and other hull features, before proceeding to prototype.

Expressions of interest are welcome.

COST

EFFECTIVENESS

Many

navies are operating mine hunters of considerable age. Typically a navy

may have a fleet of 6 or 7 mine hunters around 10 years old or more -

operating around the clock. With the call for energy savings, the

Dragonfly may be seen as an attractive proposition, but purchasing

departments will want to know more about performance.

The

position is that Bluebird Marine Systems have a test programme under way

to prove the low drag hull-form and energy harvesting systems. The

advanced SWASH platform is active to be able to reduce running drag

with feedback from energy tracking systems. A target sprint capacity of

10+ knots for 10+ hours is looking achievable, with return to continuous

cruising 24/7 of 7-10 knots unaffected. This of course depends on the

motor/battery combination that a customer might specify.

A

fleet of 10 Dragonflies will cover more area at significantly less cost

than 6 or 7 larger, conventional crewed ships. The real attraction is that

where energy savings

are being called for, 10 Dragonflies will virtually eliminate fuel usage,

hence pollution all at the same time - and still sweep more area. 10

Dragonflies should halve the replacement bill against 6 or more

conventional ships.

We

are suggesting that this is worth waiting for, and that if sufficient

interest is made known, that the development programme may be accelerated

to enable supply well in advance of the 2020 and 2025 25% renewable energy

target dates.

BUILD

UNDER LICENSE

Navies

may attain licenses to deploy the technology via existing shipbuilding

contractors, or specific vessel designs, from Bluebird Marine System Ltd

as a single source acquisition; subject to contract.

1/20th scale robotic rest models will shortly be made available for

customers to conduct their own evaluation tests. These models will be

somewhere in the region of $40-50,000. Reserve your place in the queue now

for delivery in 2014.

Expressions

of interest to: bluefish@bluebird-electric.net.

All enquiries will be dealt with in the strictest of commercial

confidence.

AUTOMATION

Mine

hunting

operations advanced the moment robotics were applied. An

autonomous mine hunter does not need a crew, though the Dragonfly class provides

life support for a crew as part of the package. A robot ship plies the oceans logging

and identifying objects for immediate removal, or for removal in time of war. The Dragonfly ship is named after the insect,

which also has wings and a time as an aquatic feeder as a nymph.

The

Dragonfly may be equipped with roving UUVs to be able to deal with mines

that it finds, remotely from shore-based headquarters anywhere in the

world. Dragonfly is also equipped with the latest navigation aids to

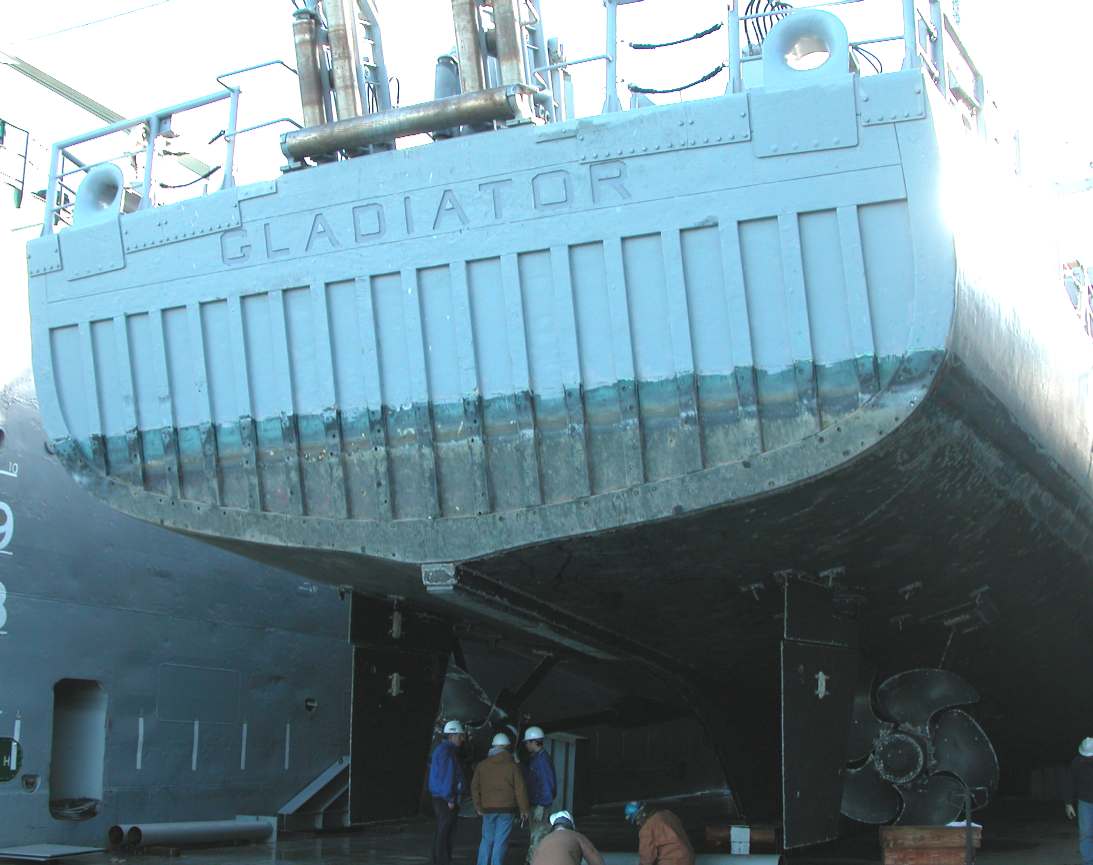

prevent collision with other ships, or subsea obstructions. The German

mine hunter below could have avoided this mishap, if it had been so

equipped. Continued use of such inefficient technology may result in navy

budgets running aground. Automation is the key to cost cutting without

skimping on results.

SPECIFIC

MILITARY APPLICATIONS -

|

•

Intelligence, Surveillance, Reconnaissance

•

Mine Countermeasures

•

Expeditionary Warfare

•

Submarine

Countermeasures

•

Explosive Ordnance Disposal

•

Anti pirate patrols |

|

•

Tactical Oceanography

• Laying and charting of Pipelines

• Construction of bridges and tunnels

• Searching for wrecks / obstacles

• Processing / Drawing of charts

• Route / Site surveys |

|

|

|

A

Dragonfly ASV may be operated in conjunction with an onboard (Mantis) ROV

via a special launch and recovery system. Once the Dragonfly has

located an enemy mine, it alerts HQ automatically to request instructions

as to logging and destruction. Destruction may be a priority in war zones,

when, under the watchful eye of a shore-based operator the ROV is

launched, plants an explosive and returns to its mother-ship. The move to

an automated navy may be justified on grounds of efficiency, economics and

to eliminate the need to put the lives of sailors at risk.

German Navy Type 332 Frankenthal class mine hunter M106 Grömitz (built 1994) based in Kiel on rocks where it grounded in the night of Feb 21

2007 off the harbor Floræ on way to Bergen. Cause of the grounding was said to be a navigational error, but the small island could possible not be detected by radar in snowy conditions.

The ship was underway with other NATO

units within a mine hunting exercise.

THE

COMPETITION

The Sandown

ship is a class of minehunter originally built for the British

Royal Navy. Sandown-class vessels also serve with the Royal Saudi Navy and the

Estonian Navy (Merevägi). The first vessel was commissioned into Royal Navy service on 9 June 1989.

All of the British ships are named after coastal towns and cities.

These small (53 m) fibreglass vessels are single role mine hunters (SRMH) rather than minesweepers. Twelve ships were built for the Royal Navy and three ships were exported to

Saudi Arabia. Three Royal Navy vessels were decommissioned following the Strategic Defence Review in 2003; Sandown (January 2005), Inverness (April 2005) and Bridport (July 2004). A further ship, Cromer, was decommissioned and transferred to a training role at the Britannia Royal Naval College in Dartmouth in 2001 as Hindostan.

The three decommissioned vessels were sold to Estonia in September 2006. They were re-equipped with TCS (Tactical Control System) and the Atlas Elektronik Seafox ROV for mine disposal. The sonar system will be also be updated. The first ship (ex Sandown), delivered in 2007, has been named Admiral

Cowan, the second (ex-Inverness), was delivered in 2008 and named Sakala and the last (ex-Bridport) named Ugandi in 2009.

SPECIFICATIONS

Type: Single role mine hunter

Displacement: 484 tons

Length: 52.5 m

Beam: 10.9 m

Draught: 2.3 m

Propulsion: Paxman Valenta 6RP200E diesels 1523 shp, diesel-electric drive

Voith Schneider Propellers

Schottel bow thrusters

Speed: 13 kts diesel, 6.5 kts electric

Complement: 34 (7 officers)

Sensors and processing systems: Kelvin Hughes 1007 navigation radar

Thales 2093 variable-depth sonar

Armament: 30 mm KCB gun

7.62 mm GPMG machine guns

Remote controlled submersibles as mine countermeasures

| Name |

Pennant number |

Builder |

Launched |

Commissioned |

Home port |

Status |

| Royal Navy |

| Sandown |

M101 |

Vosper

Thornycroft, Woolston |

1988 |

1989 |

|

Sold to Estonia as Admiral

Cowan |

| Inverness |

M102 |

Vosper Thornycroft |

1990 |

1991 |

|

Sold to Estonia as Sakala |

| Cromer |

M103 |

Vosper Thornycroft |

1990 |

1992 |

Dartmouth |

Training ship, renamed

Hindostan |

| Walney |

M104 |

Vosper Thornycroft |

1991 |

1992 |

Faslane |

decommissioned |

| Bridport |

M105 |

Vosper Thornycroft |

1992 |

1993 |

|

Sold to Estonia as Ugandi |

| Penzance |

M106 |

Vosper Thornycroft |

1997 |

1998 |

Faslane |

Active |

| Pembroke |

M107 |

Vosper Thornycroft |

1997 |

1998 |

Faslane |

Active |

| Grimsby |

M108 |

Vosper Thornycroft |

1998 |

1999 |

Faslane |

Active |

| Bangor |

M109 |

Vosper Thornycroft |

1999 |

1999 |

Faslane |

Active |

| Ramsey |

M110 |

Vosper Thornycroft |

1999 |

2000 |

Faslane |

Active |

| Blyth |

M111 |

Vosper Thornycroft |

2000 |

2001 |

Faslane |

Active |

| Shoreham |

M112 |

Vosper Thornycroft |

2001 |

2001 |

Faslane |

Active |

| Royal

Saudi Arabian Navy |

| Al Jawf |

|

Vosper Thornycroft |

|

|

|

|

| Shaqra |

|

Vosper Thornycroft |

|

|

|

|

| Al Kharj |

|

Vosper Thornycroft |

|

|

|

|

| Estonian

Navy |

| Admiral Cowan |

M313 |

Vosper Thornycroft |

1988 |

2007 |

Tallinn |

Active |

| Sakala |

M314 |

Vosper Thornycroft |

1990 |

2008 |

Tallinn |

Active |

| Ugandi |

M315 |

Vosper Thornycroft |

1992 |

2009 |

Tallinn |

Active |

NATO

25 JANUARY 2013

Standing

NATO Mine-Countermeasures Group 2, is a multinational, integrated maritime

force - made up of vessels from various allied nations, training and

operating together as a single team - that is permanently available to

NATO to perform a wide range of tasks, from participating in exercises to

crisis response and real world operational missions. Usually the Force is

employed in the Mediterranean area but, as necessary, will be available

anywhere NATO requires it to deploy.

SNMCMG1

left the port of Gdynia, Poland, on

Monday the 21st January with a new commander at the helm and new ships.

The first days at sea are usually used for ships and crew to get

acquainted with the new command and with the respective capabilities of

each vessel - this is called a shakedown cruise.

The

Dragonfly class mine-hunter would save the cost of fuel, crew provisions

and remuneration. Autonomous ships are active 24 hours a day continuously,

365 days a year. They too can effect a crisis response, and they can

operate in perfect synchronization with one another. The hullform is far

more stable and adaptable to changing conditions. They operate without polluting

the oceans for sustainable operations.

NATO

mine countermeasures operation 2013

MINE

HISTORY

CONTACT

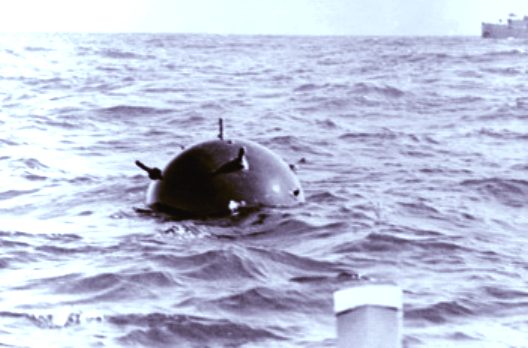

MINES

The earliest mines were usually of this type. They are still used today, as they are extremely low cost compared to any other anti-ship weapon and are effective, both as a terror weapon and to sink enemy ships. Contact mines need to be touched by the target before they detonate, limiting the damage to the direct effects of the explosion and usually affecting only the single vessel that triggers them.

Early mines had mechanical mechanisms to detonate them, but these were superseded in the 1870s by the Hertz Horn (or chemical horn), which was found to work reliably even after the mine had been in the sea for several years. The mine's upper half is studded with hollow lead protuberances, each containing a glass vial filled with sulfuric acid. When a ship's hull crushes the metal horn, it cracks the vial inside it, allowing the acid to run down a tube and into a lead-acid battery which until then contains no acid electrolyte. This energizes the battery, which detonates the explosive.

Earlier forms of the detonator employed a vial of sulfuric acid surrounded by a mixture of potassium perchlorate and

sugar. When the vial was crushed, the acid ignited the perchlorate / sugar mix, and the resulting flame ignited the gunpowder charge.

During the initial period of World War I, the British Navy used contact mines in the English Channel and later in large areas of the North Sea to hinder patrols by German submarines. Later, the American antenna mine was widely used because submarines could be at any depth from the surface to the seabed. This type of mine had a copper wire attached to a buoy that floated above the explosive charge which was weighted to the seabed with a steel cable. If a submarine's steel hull touched the copper wire, the

slight voltage change caused by contact between two dissimilar metals was amplified and detonated the explosives.

LIMPET MINES

Limpet mines are a special form of contact mine which are attached to the target by magnets and left, and are so named because of the superficial similarity to the limpet, a mollusk.

MOORED CONTACT MINES

Generally, this mine type is set to float just below the surface of the water or as deep as five meters. A steel cable connecting the mine to an anchor on the seabed prevents it from drifting away. The explosive and detonating mechanism is contained in a buoyant metal or plastic shell. The depth below the surface at which the mine floats can be set so that only deep draft vessels such as aircraft carriers, battleships or large cargo ships are at risk, saving the mine from being used on a less valuable target. In littoral waters it is important to ensure that the mine does not become visible when the sea level falls at low tide, so the cable length is adjusted to take account of tides. Even during the Second World War, there were mines that could be moored in 300m-deep

water (Example: The U.S. Mark 6).

Floating mines typically have a mass of around 200 kg, including 80 kg of explosives e.g.

TNT, minol or amatol.

During WWII mine traps were used for blocking port entrances. Two floating mines were anchored some distance apart on either side of a shipping channel, linked by a chain. When a deep draft vessel passed through the trap it would pull the

chain along with it, dragging the mines onto the sides of the

ship; the resulting double explosion often sank it. This system was not used extensively, but proved effective in blocking ports.

Drifting contact mines

Drifting mines were occasionally used during World War I and World War II. However, they were more feared than effective. Sometimes floating mines break from their moorings and become drifting mines; modern mines are designed to deactivate in this event. After several years at sea, the deactivation mechanism might not function as intended and the mines may remain live. Admiral Jellicoe's British fleet did not pursue and destroy the outnumbered German High Seas Fleet when it turned away at the Battle of Jutland because he thought they were leading him into a trap: he believed it possible that the Germans were either leaving floating mines in their wake, or were drawing him towards

submarines, although neither of these was the case.

Churchill promoted "Operation Royal Marine" in 1940 and again in 1944 where floating mines were put into the Rhine in France to float down the river, becoming active after a time calculated to be long enough to reach German territory.

After World War I the drifting contact mine was banned, but was occasionally used during

World War II. The drifting mines were much harder to remove than tethered mines after the war, and they caused about the same damage to both sides.

Bottom contact mines

A bottom contact mine is the simplest form of mine. It is merely an explosive charge with some form of fuze fitted lying on the seafloor. They have been used against submarines, as submarines sometimes lie on the seafloor to reduce their acoustic signature. They are also used to prevent landing craft from reaching the shore and were a major obstacle during the D-Day landings. The

Germans used

antitank mines here with minor modifications to make them more reliable underwater, attaching the mines to the front of many of the obstacles seen in photos of the landing.

These mines usually weighed 2 to 50 kg, including 1 to 40 kg of explosives (TNT or hexatonal).

Remotely controlled mines

Frequently used in combination with coastal artillery and hydrophones, controlled mines (or command detonation mines) can be in place in peacetime, which is a huge advantage in blocking important shipping routes. The mines can usually be turned into "normal" mines with a switch (which prevents the enemy from simply capturing the controlling station and deactivating the mines), detonated on a signal or be allowed to detonate on their own. The earliest ones were developed around 1812 by

Robert Fulton. The first remotely controlled mines were moored mines used in the

American Civil War, detonated electrically from shore. They were considered superior to contact mines because they did not put friendly shipping at risk.

Modern examples usually weigh 200 kg (440 lb), including 80 kg (175 lb) of explosives (TNT or hexatonal).

Influence mines

These mines are triggered by the influence of a ship or submarine, rather than direct contact. Such mines incorporate electronic sensors designed to detect the presence of a vessel and detonate when it comes within the blast range of the warhead. The fuzes on such mines may incorporate one or more of the following sensors:

magnetic, passive acoustic or water pressure displacement caused by the proximity of a vessel.

First used during the First World War, their use became more general in the Second World War. The sophistication of influence mine fuzes has increased considerably over the years as first transistors and then microprocessors have been incorporated into designs. Simple magnetic sensors have been superseded by total-field magnetometers. Whereas early magnetic mine fuzes would respond only to changes in a single component of a target vessel's magnetic field, a total field magnetometer responds to changes in the magnitude of the total background field (thus enabling it to better detect even degaussed ships). Similarly, the original broadband hydrophones of 1940s acoustic mines (which operate on the integrated volume of all frequencies) have been replaced by narrow-band sensors which are much more sensitive and selective. Mines can now be programmed to listen for highly specific acoustic signatures (e.g. a gas turbine powerplant and/or cavitation sounds from a particular design of propeller) and ignore all others. The sophistication of modern electronic mine fuzes incorporating these Digital Signal Processing capabilities makes it much more difficult to detonate the mine with electronic countermeasures because several sensors working together (e.g. magnetic, passive acoustic and water pressure) allow it to ignore signals which are not recognised as being the unique signature of an intended target vessel.

Modern influence mines such as the BAE Stonefish are computerised, with all the programmability that this implies e.g. the ability to quickly load new acoustic signatures into fuzes, or program them to detect a single, highly distinctive target signature. In this way, a mine with a passive acoustic fuze can be programmed to ignore all friendly vessels and small enemy vessels, only detonating when a very large enemy target passes over it. Alternatively, the mine can be programmed specifically to ignore all surface vessels regardless of size and exclusively target submarines.

Even as far back as the Second World War it was possible to incorporate a "ship counter" facility into mine fuzes e.g. set the mine to ignore the first two ships to pass over it (which could be mine-sweepers deliberately trying to trigger mines) but detonate when the third ship passes overhead

- which could be a high-value target such as an aircraft carrier or

oil tanker. Even though modern mines are generally powered by a long life

lithium battery, it is important to conserve power because they may need to remain active for months or even years. For this reason, most influence mines are designed to remain in a semi-dormant state until an

un-powered (e.g. deflection of a mu-metal needle) or low-powered sensor detects the possible presence of a vessel, at which point the mine fuze powers up fully and the passive acoustic sensors will begin to operate for some minutes. It is possible to program

computerised mines to delay activation for days or weeks after being laid; similarly, they can be programmed to self-destruct or render themselves safe after a preset period of time, e.g., 12 days or 12 months. Generally, the more sophisticated the mine design, the more likely it is to have some form of anti-handling device fitted in order to hinder clearance by

divers or remotely piloted submersibles.

A

Norwegian mine sweeper and an Textron MAPC AAI unmanned drone, robotic mine hunter.

Both vessels reliant on fossil fuels that seriously limit operational

range, hence mission duration. The US Navy sponsors the popular Roboboat

competition because they recognize that the future of certain persistent

operations will be best handled by robots. The developers of the Dragonfly

take the same view, building on that with a high speed zero carbon

platform, that because it may operate continuously without being tied to

diesel refueling stops, is far more productive.

Moored mines

The moored mine is the backbone of modern mine systems. They are deployed where water is too deep for bottom mines. They can use several kinds of instruments to detect an enemy, usually a combination of acoustic, magnetic and pressure sensors, or more sophisticated optical shadows or electro potential sensors. These cost many times more than contact mines. Moored mines are effective against most kinds of ships. As they are cheaper than other anti-ship weapons they can be deployed in large numbers, making them useful area denial or "channelizing" weapons. Moored mines usually have lifetimes of more than 10 years, and some almost unlimited. These mines usually weigh 200 kg (440 lb), including 80 kg (175 lb) of explosives (hexatonal). In excess of 150 kg (330 lb) of explosives the mine becomes inefficient, as it becomes too large to handle and the extra explosives add little to the mine's effectiveness.

By way as an example as to effectiveness, a moored mine sank the Britannic

during the First World War.

Bottom mines

Bottom mines are used when the water is no more than 60 meters (180 ft) deep or when mining for submarines down to around 200 meters (660 ft). They are much harder to detect and sweep, and can carry a much larger warhead than a moored mine. Bottom mines commonly utilize multiple types of sensors, which are less sensitive to sweeping.

These mines usually weigh between 150 and 1,500 kilograms (330 to 3,300 pounds), including between 125 and 1,400 kg (275 to 3,090 pounds) of explosives.

Bouquet mine

The bouquet mine is a single anchor attached to several floating mines. It is designed so that when one mine is swept/detonated, another takes its place. It is a very sensitive construction and lacks reliability.

Anti sweep mine

The anti sweep mine is a very small mine (40 kg warhead) with as small a floating device as possible. When the wire of a mine sweep hits the mine, it "sinks", letting the sweep wire drag along the anchoring wire of the mine until the sweep hits the mine. That detonates the mine and cuts the sweeping wire. They are very cheap and usually used in combination with other mines in a minefield to make sweeping more difficult. One type is the Mark 23 used by the

United States during World War II.

Oscillating mine

The mine is hydrostatically controlled to maintain a pre-set depth below the

water's surface independently of the rise and fall of the tide.

Ascending mine

The ascending mine is a floating distance mine that may cut its mooring or in some other way float higher when it detects a target. It lets a single floating mine cover a much larger depth range.

Homing Mine

This is another name for the rocket mine or torpedo mine.

ROCKET, HOMING or TORPEDO MINES

A Russian invention, the rocket mine is a bottom distance mine that fires a homing high-speed rocket (not torpedo) upwards towards the target. It is intended to allow a bottom mine to attack surface ships as well as submarines from a greater depth. One type is the Te-1

rocket propelled mine.

Torpedo mine

The torpedo mine is a self-propelled variety, able to lie in wait for a target and then pursue it e.g. the Mark 60 CAPTOR. Other designs such as the Mk 67 Submarine Launched Mobile Mine (which is based on a Mark 37 torpedo) are capable of swimming as far as 10 miles through or into a channel, harbor, shallow water area and other zones which would normally be inaccessible to craft laying the device. After reaching the target area they sink to the sea bed and act like conventionally laid influence mines. Generally,

torpedo mines incorporate computerised acoustic and magnetic

fuses.

The U.S. Mark 24 "mine", code-named FIDO, was actually an ASW homing torpedo. The mine designation was disinformation to conceal its function.

Mobile mine

The mine is propelled to its intended position by propulsion equipment such as a torpedo. After reaching its destination, it sinks to the

seabed and operates like a standard mine.

Nuclear mine

During the Cold War a test was conducted with naval mine fitted with tactical nuclear warheads for the "Baker" shot of Operation Crossroads. This weapon was experimental and never went into production. There have been some reports that North

Korea may be developing a nuclear mine The Seabed Arms Control Treaty prevents the placement of nuclear weapons on the seabed beyond a 12-mile coast zone.

Daisy-chained mine

This comprises two moored, floating contact mines which are tethered together by a length of steel cable or chain. Typically, each mine is situated approximately 60 feet (18 m) away from its neighbour, and each floats a few metres below the surface of the ocean. When the target ship hits the

steel cable, the mines on either side are drawn down the side of the ship's hull, exploding on contact. In this manner it is almost impossible for target ships to pass safely between two individually moored mines. Daisy-chained mines are a very simple concept which was used during the Second World War.

PlanetSolar

has set the benchmark for ocean surveying using solar energy. It works. We

are simply offering a faster platform, that makes persistent operations

economically sound as well as non polluting. Development such as this

could take many years if support for the concept is subject to the

traditional resistance to change.

We live in a world where technology is advancing so fast, that if you

don't take note of maritime development, you will be going backwards.

Computers are a good example of this. Laptops and software that we were

thrilled by just 2 years ago is now an obsolete and ponderous liability

with mobile phone communications also in the fast lane. Military

requisitions of such equipment is frequently out of date before an order

can be approved by executive officers.

Dummy mine

Plastic drums filled with sand or concrete are periodically rolled off the side of ships as real mines are laid in large mine-fields. These inexpensive false targets (designed to be of a similar shape and size as genuine mines) are intended to slow down the process of mine clearance: a mine-hunter is forced to investigate each suspicious sonar contact on the sea bed, whether it is real or not. Often a maker of

Naval mines will provide both training and dummy versions of their mines.

Mine laying

Historically several methods were used to lay mines. During the First and Second World Wars, the Germans used

U-boats to lay mines around the

UK. In the Second World War, aircraft came into favour for mine laying with the one of largest such examples being the mining of the

Japanese sea routes in Operation Starvation.

Laying a minefield is a relatively fast process with specialized ships, which is still today the most common method. These minelayers can carry several thousand mines and manoeuvre with high precision. The mines are dropped at a predefined interval into the water behind the ship. Each mine is recorded for later clearing, but it is not unusual for these recordings to be lost together with the ships. Therefore many countries demand that all mining operations shall be planned on land and records kept so the mines can later be recovered more easily.

Other methods to lay minefields include:

* Converted merchant ships – rolled or slid down ramps

* Aircraft – descent to the water is slowed by a parachute

* Submarines – launched from torpedo tubes or deployed from * specialized mine racks on the sides of the submarine

* Combat boats – rolled off the side of the boat

* Camouflaged boats – masquerading as fishing boats

* Dropping from the shore – typically smaller, shallow-water mines

* Attack divers – smaller shallow-water mines

In some cases, mines are automatically activated upon contact with the water. In others, a safety lanyard is pulled (e.g. one end attached to the rail of a ship,

aircraft or torpedo tube) which starts an automatic timer countdown before the arming process is complete. Typically, the automatic safety-arming process takes some minutes to complete. This is in order to give the people laying the mines sufficient time to move out of its activation/blast zone.

Aerial mining in World War II

In the 1930s, Germany had experimented with the laying of mines by aircraft; it became a crucial element in their overall mining strategy. Aircraft had the advantage of speed, and they would never get caught in their own minefields. German mines held a large 1,000 lb. (450 kg) explosive charge. From April to June 1940, the Luftwaffe laid 1,000 mines in British waters. Soviet ports were mined, as was the Arctic convoy route to Murmansk. The Heinkel He 115 could carry two medium or one large mine while the Heinkel He 59, Dornier Do 18, Junkers Ju 88 and Heinkel He 111 could carry more.

Soviet Union

The USSR was relatively ineffective in its use of naval mines in WWII in comparison with its record in previous wars. Small mines were developed for use in rivers and lakes, and special mines for shallow water. A very large chemical mine was designed to sink through ice with the aid of a melting compound. Special aerial mine designs finally arrived in 1943–1944, the AMD-500 and AMD-1000. Various

Soviet Naval Aviation torpedo bombers were pressed into the role of aerial mining in the Baltic Sea and the Black Sea, including Ilyushin DB-3s, Il-4s and Lend Lease Douglas Boston IIIs.

United Kingdom

In September 1939, the UK announced the placement of extensive defensive minefields in waters surrounding the Home Islands. Offensive aerial mining operations began in April 1940 when 38 mines were laid at each of these locations: the Elbe River, the port of Lübeck and the German naval base at Kiel. In the next 20 months, mines delivered by aircraft sank or damaged 164 Axis ships with the loss of 94 aircraft. By comparison, direct aerial attacks on Axis shipping had sunk or damaged 105 vessels at a cost of 373 aircraft lost. The advantage of aerial mining became clear, and the

United Kingdom geared up for it. A total of 48,000 aerial mines were laid by the Royal Air Force (RAF) in the European Theatre during World War II.

United States

The United States's early aerial mining efforts used smaller aircraft unable to carry many mines. Using TBF Avenger torpedo bombers, the

US Navy mounted a direct aerial mining attack on enemy shipping in Palau on 30 March 1944 in concert with simultaneous conventional bombing and strafing attacks. The dropping of 78 mines stopped 32 Japanese ships from escaping Koror harbor; the combined operation sank or damaged 36 ships. Two Avengers were lost; their crews were recovered. The mines brought port usage to a halt for 20 days; further mine-laying in the area contributed to the Japanese abandoning Palau as a base.

As early as 1942, American mining experts such as Naval Ordnance Laboratory scientist Dr. Ellis A. Johnson, Commander, Naval Reserve, suggested massive aerial mining operations against Japan's "outer zone" (Korea and northern

China) as well as the "inner zone", their home islands. First, aerial mines would have to be developed further and manufactured in large numbers. Second, laying the mines would require a sizable air group. The US

Army Air Force had the carrying capacity but considered mining to be the

Navy's job. The US Navy lacked suitable aircraft. Johnson set about convincing General Curtis LeMay of the efficacy of very heavy bombers laying aerial mines.

In the meantime, B-24 Liberator, PBY Catalina and other available bomber aircraft took part in localized mining operations in the Southwest Pacific and the China Burma India (CBI) Theaters, beginning with a very successful attack on the Yangon River in February 1943. Aerial minelaying operations involved a coalition of British, Australian and American aircrews, with the RAF and the Royal

Australian Air Force (RAAF) carrying out 60% of the sorties and the

USAAF and US Navy covering 40%. Both British and American mines were used. Japanese merchant shipping suffered tremendous losses, while Japanese mine sweeping forces were spread too thin attending to far-flung ports and extensive coastlines. Admiral Thomas C. Kinkaid, who directed nearly all RAAF mining operations in CBI, heartily endorsed aerial mining, writing in July 1944 that "aerial mining operations were of the order of 100 times as destructive to the enemy as an equal number of bombing missions against land targets."

Finally, in March 1945, Operation Starvation began in earnest, using 160 of LeMay's B-29 Superfortress bombers to attack Japan's inner zone. Almost half of the mines were the US-built Mark 25 model, carrying 1250 lbs of explosives and weighing about 2,000 lbs. Other mines used included the smaller 1,000 lb Mark 26. 15 B-29s were lost while 293 enemy merchant ships were sunk or

damaged. 12,000 aerial mines were laid, a significant barrier to Japan's access to outside resources. Prince Fumimaro Konoe said after the war that the aerial mining by B-29s had been "equally as effective as the B-29 attacks on Japanese industry at the closing stages of the war when all food supplies and critical material were prevented from reaching the

Japanese home islands." The United States

Strategic Bombing Survey

(Pacific War) concluded that it would have been more efficient to combine the United States's effective anti-shipping submarine effort with land- and carrier-based air power to strike harder against merchant shipping and begin a more extensive aerial mining campaign earlier in the war. Survey analysts projected that this would have starved Japan, forcing an earlier end to the war. After the war, Dr. Johnson looked at the Japan inner zone shipping results, comparing the total economic cost of submarine-delivered mines versus air-dropped mines and found that, though 1 in 12 submarine mines connected with the enemy as opposed to 1 in 21 for aircraft mines, the aerial mining operation was about ten times less expensive per enemy ton sunk.

Clearing WWII aerial mines

Between 600,000 and 1,000,000 naval mines of all types were laid in World War II. Advancing military forces worked to clear mines from newly taken areas, but extensive minefields remained in place after the war. Air-dropped mines had an additional problem for mine sweeping operations: they were not meticulously charted. In Japan, much of the B-29 mine-laying work had been performed at high altitude, with the drifting on the wind of mines carried by parachute adding a randomizing factor to their placement. Generalized danger areas were identified, with only the quantity of mines given in detail. Mines used in Operation Starvation were supposed to be self-sterilizing, but the circuit did not always work. Clearing the mines from Japanese waters took so many years that the task was eventually given to the Japan Maritime Self-Defense Force.

For the purpose of clearing all types of naval mines, the Royal Navy employed German crews and minesweepers from June 1945 to January 1948, organised in the German Mine Sweeping Administration, the GMSA, which consisted of 27,000 members of the former Kriegsmarine and 300 vessels. Mine clearing wasn't always successful: a number of ships were damaged or sunk by mines after the war. Two such examples were the Liberty ships Pierre Gibault which was scrapped after hitting a mine in a previously cleared area off the

Greek island of Kythira in June 1945, and Nathaniel Bacon which hit a minefield off Civitavecchia,

Italy in December 1945, caught fire, was beached, and broke in two.

Damage

The damage that may be caused by a mine depends on the "shock factor value", a combination of the initial strength of the explosion and of the distance between the target and the detonation. When taken in reference to ship hull plating, the term "Hull Shock Factor" (HSF) is used, while keel damage is termed "Keel Shock Factor" (KSF). If the explosion is directly underneath the keel, then HSF is equal to KSF, but explosions that are not directly underneath the ship will have a lower value of KSF.

Direct damage

Usually only created by contact mines, direct damage is a hole blown in the ship. Among the crew, fragmentation wounds are the most common form of damage. Flooding typically occurs in one or two main watertight compartments which can sink smaller ships or disable larger ones. Contact mine damage often occurs at or close to the waterline near the bow, but depending on circumstances a ship could be hit anywhere on its outer hull surface (the USS Samuel B Roberts mine attack being a good example of a contact mine detonating amidships and underneath the ship).

Bubble jet effect

The bubble jet effect occurs when a mine detonates in the water a short distance away from the ship. The explosion creates a bubble in the water, and due to the difference in pressure, the bubble will collapse from the bottom. The bubble is buoyant and so it rises towards the surface. If the bubble reaches the surface as it collapses it can create a pillar of water that can go over a hundred meters into the air (a "columnar plume"). If conditions are right and the bubble collapses onto the ship's hull the damage to the ship can be extremely serious; the collapsing bubble forms a high energy jet that can break a meter wide hole straight through the ship, flooding one or more compartments, and is capable of breaking smaller ships apart. The

crew in the areas hit by the pillar are usually killed instantly. Other damage is usually limited.

The Baengnyeong incident, in which the ROKS Cheonan broke in half and sank off the coast South Korea in 2010, is thought by some to have been caused by the bubble jet effect.

Shock effect

If the mine detonates at a distance from the ship, the change in water pressure causes the ship to resonate. This is frequently the most deadly type of explosion, if it is strong enough. The whole ship is dangerously shaken and everything onboard is tossed around.

Engines rip from their beds, cables from their holders, etc. A badly shaken ship usually sinks quickly, with hundreds, or even thousands of small leaks all over the ship and no way to power the pumps. The crew fare no better, as the violent shaking tosses them

around. This shaking is powerful enough to cause disabling injury to knees and other joints in the body, particularly if the affected person stands on surfaces connected directly to the hull (such as steel decks).

The resulting gas cavitation and shock-front-differential over the width of the human body is sufficient to stun or kill divers.

Countermeasures

Weapons are frequently a few steps ahead of countermeasures, and mines are no exception. In this field the British, with their large seagoing navy, have had the bulk of world experience, and most anti-mine developments, such as

de-gaussing and the double-L sweep were British inventions. When on operational missions, such as the recent invasion of Iraq, the US still rely on British and

Canadian minesweeping services. The US has worked on some innovative mine hunting countermeasures, such as the use of military

dolphins to detect and flag mines. However, they are of questionable effectiveness.

Passive countermeasures

Ships can be designed to be difficult for mines to detect, to avoid detonating them. This is especially true for minesweepers and mine hunters that work in minefields, where a minimal signature outweighs the need for armour and speed. These ships have hulls of glass fibre or wood instead of steel to avoid magnetic signatures, they use special propulsion systems, such as Voith-Schneider

propellers, to limit the acoustic signature. They are built with hulls that produce a minimal pressure signature. These measures create other problems. They are expensive, slow, and vulnerable to enemy fire. Therefore, they need protection. Many modern ships have a mine-warning sonar—a simple

sonar looking forward and warning the crew if it detects possible mines ahead. It is only effective when the ship is moving slowly.

A steel-hulled ship can be degaussed (more correctly, de-oerstedted or depermed) using a special degaussing station that contains many large coils and induces a

magnetic field in the hull with alternating current to demagnetize the hull. This is a rather problematic solution, as magnetic

compasses need recalibration and all metal objects must be kept in exactly the same place. Ships slowly regain their magnetic field as they travel through the Earth's magnetic field, so the process has to be repeated every six months.

A simpler variation of this technique, called wiping, was developed by Charles F. Goodeve which saved time and resources.

Between 1941 and 1943 the US Naval Gun factory (a division of the Naval Ordnance Laboratory) in Washington D.C. built physical models of all US Naval ships. Three kinds of steel were used in shipbuilding: mild steel for bulkheads, a mixture of mild steel and high tensile steel for the hull, and special treatment steel for armor plate. The models were placed within coils which could simulate the Earth's magnetic field at any location. The magnetic signatures were measured with degaussing coils. The objective was to reduce the vertical component of the combination of the Earth's field and the ship's field at the usual depth of German mines. From the measurements, coils were placed and coil currents determined to minimize the chance of detonation for any ship at any heading at any latitude.

Some ships are built with magnetic inductors, large coils placed along the ship to counter the ship's magnetic field. Using magnetic probes in strategic parts of the ship, the strength of the current in the coils can be adjusted to minimize the total magnetic field. This is a heavy and clumsy solution, suited only to small-to-medium sized ships.

Boats typically lack the generators and space for the solution, while the amount of power needed to overcome the magnetic field of a large ship is impractical.

Active countermeasures

Active countermeasures are ways to clear a path through a minefield or remove it completely. This is one of the most important tasks of any mine warfare flotilla.

Mine sweepingA sweep is either a contact sweep, a wire dragged through the water by one or two ships to cut the mooring wire of floating mines, or a distance sweep that mimics a ship to detonate the mines. The sweeps are dragged by minesweepers, either purpose-built military ships or converted trawlers. Each run covers between one and two hundred meters, and the ships must move slowly in a straight line, making them vulnerable to enemy fire. This was exploited by the

Turkish army in the Battle of Gallipoli in 1915, when mobile howitzer batteries prevented the British and

French from clearing a way through minefields.

If a contact sweep hits a mine, the wire of the sweep rubs against the mooring wire until it is cut. Sometimes "cutters", explosive devices to cut the mine's wire, are used to lessen the strain on the sweeping wire. Mines cut free are recorded and collected for research or shot with a deck gun.

Minesweepers protect themselves with an oropesa or paravane instead of a second minesweeper. These are torpedo-shaped towed bodies, similar in shape to a Harvey Torpedo, that are streamed from the sweeping vessel thus keeping the sweep at a determined depth and position. Some large warships were routinely equipped with paravane sweeps near the bows in case they inadvertently sailed into minefields—the mine would be deflected towards the paravane by the wire instead of towards the ship by its wake. More recently, heavy-lift

helicopters have dragged minesweeping sleds, as in the 1991

Persian Gulf War.

The distance sweep mimics the sound and magnetism of a ship and is pulled behind the sweeper. It has floating coils and large underwater drums. It is the only sweep effective against bottom mines.

During the Second World War, RAF Coastal Command used Vickers Wellington bombers Wellington DW.Mk I fitted with degaussing coils to trigger magnetic mines.

Modern influence mines are designed to discriminate against false inputs and are therefore much harder to sweep. They often contain inherent anti-sweeping mechanisms. For example, they may be programmed to respond to the unique noise of a particular ship-type, its associated magnetic signature and the typical pressure displacement of such a vessel. As a result, a

mine-sweeper must accurately guess and mimic the required target signature in order to trigger detonation. The task is complicated by the fact that an influence mine may have one or more of a hundred different potential target signatures programmed into it.

Another anti-sweeping mechanism is a ship-counter in the mine fuze. When enabled, this allows detonation only after the mine fuze has been triggered a pre-set number of times. To further complicate matters, influence mines may be programmed to arm themselves (or disarm automatically—known as self-sterilization) after a pre-set time. During the pre-set arming delay (which could last days or even weeks) the mine would remain dormant and ignore any target stimulus, whether genuine or faked.

When influence mines are laid in an ocean minefield, they may have various combinations of fuze settings configured. For example, some mines (with the acoustic sensor enabled) may become active within three hours of being laid, others (with the acoustic and magnetic sensors enabled) may become active after two weeks but have the ship-counter mechanism set to ignore the first two trigger events, and still others in the same minefield (with the magnetic and pressure sensors enabled) may not become armed until three weeks have passed. Groups of mines within this mine-field may have different target signatures which may or may not overlap. The fuzes on influence mines allow many different permutations, which complicates the clearance process.

Mines with ship-counters, arming delays and highly specific target signatures in mine fuzes can falsely convince a belligerent that a particular area is clear of mines or has been swept effectively because a succession of vessels have already passed through safely.

Mine huntingMine hunting is very different from sweeping, although some minehunters can do both tasks. Mines are hunted using sonar, then inspected and destroyed either by divers or ROVs (remote controlled unmanned mini submarines). It is slow, but also the most reliable way to remove mines. Mine hunting started during the Second World War, but it was only after the war that it became truly effective.

Sea mammals (mainly the Bottlenose Dolphin) have been trained to hunt and mark mines, most famously by the U.S. Navy Marine Mammal Program. Mine-clearance dolphins were deployed in the Persian Gulf during the

Iraq War in 2003. The Navy claims that these dolphins were effective in helping to clear more than 100 antiship mines and underwater booby traps from Umm Qasr Port.

French naval officer Jacques Yves Cousteau's Undersea Research Group was once involved in mine-hunting operations: They removed or detonated a variety of German mines, but one particularly defusion-resistant batch—equipped with acutely sensitive pressure, magnetic, and acoustic sensors and wired together so that one explosion would trigger the rest—was simply left undisturbed for years until corrosion would (hopefully) disable the mines.

Mine breaking

A more drastic method is simply to load a cargo ship with cargo that makes her less vulnerable to sinking (wood for example) and drive her through the minefield, letting the ship to be protected follow the same path. This method was employed by the German Kriegsmarine during WWII, using converted ships known as Sperrbrecher ("barrage breaker"). Alternatively, a shallow draught vessel can be steamed through the minefield at high speed to generate a pressure wave sufficient to trigger mines, with the

minesweeper moving fast enough to be sufficiently clear of the pressure wave so that triggered mines do not destroy the ship itself. These techniques are the only way to sweep pressure mines. The technique can be simply countered by use of a ship-counter, set to allow a certain number of passes before the mine is actually triggered. Modern doctrine calls for ground mines to be hunted rather than swept. A new system is being introduced for sweeping pressure mines however counters are going to remain a problem.

An updated form of mine breaking is the use of small unmanned ROVs that simulate the acoustic and magnetic signatures of larger ships and are built to survive exploding mines. Repeated sweeps would be required in case one or more of the mines had its "ship counter" facility enabled i.e. were programmed to ignore the first 2, 3, or even 6 target activations.

ADMIRALTY MINING ESTABLISHMENT

The Admiralty Mining Establishment was a technical department of the Royal

Navy responsible for both the design of naval mines and the development of suitable countermeasures. In keeping with many technical departments it employed both military and highly skilled, civilian personnel. It was partly located near Portsmouth naval base at West Leigh House, Havant.

During the Second World War it recruited a number of scientists to its ranks. Many of them went on to become highly regarded in their respective fields including; David Bates, Robert Boyd, Francis Crick, Tom Gaskell, John Gunn, Harrie Massey and Nevill Mott.

LINKS

Technical

details of German Second World War sea mines

'Stonefish'

– a British influence mine

Development

of Minewarfare

List

of various mine types

Description

of mines used by the United States

Henry

Norton Sulivan: a depiction of early Naval Mine

Belgian-Netherlands

Naval Mine Warfare School, NATO Center of Excellence

W.L.Clowes

in 1855

Popular

Science, March 1940, Can Mines Conqueror Sea Power

Popular

Science, November 1943, Mine Killers at Work

"Fighting

The Submarine Mine – How Navies Combat A Deadly Sea Weapon" October

1941

"Mines

Are Dirty Tricks" , February 1951

UK

National Archives leaflet on Royal Navy research and development

Wartime

use of Leigh Park House

History

of HMS Vernon http://gcaptain.com/incident-photo-of-the-week-m106-gromitz http://defense-update.com/20111208_sea-fox-naval-mine-hunter.html http://submarinersworld.blogspot.co.uk/2012/09/atlas-na-seafox-mine-neutralization.html http://www.stripes.com/news/u-s-military-enters-new-generation-of-sea-mine-warfare

|