|

CHOOSING THE BEST MARINE PROPELLER

There

are many exotic ways of generating thrust in water:

Caterpillar drives, fish-tails, paddles, thrusters, etc. But, when it

comes down to it, a good propeller is more cost effective,

reliable and available. So what is a good propeller?

The answer to that is: the one for the job.

However, there

are so many applications one must choose carefully -

prioritise. Most commercially available propellers

only achieve 40-50% efficiency. Unfortunately,

this is nowhere near enough to enable the Elizabeth

Swann to

tackle the high seas using only renewable

energy.

|

|

|

|

|

Erricson's

propeller 1842 |

A

wooden airscrew propeller |

Bronze

propeller from the Lusitania |

HISTORY Long

before there was any practical application it was

discovered that a flat plate pushed through the air at

an angle created lift. Of course a flat plate is

not very efficient. Marine

propellers work on the same principles.

Except that air is many times less dense than water and

water is virtually incompressible. Credit for the

invention of the marine screw propeller comes down to

two men: Francis petit Smith and John Ericsson. In

1836, both Smith and Ericsson obtained patents

for screw propellers of different designs. An

accident led to the discovery a shortened Archimedain

screw was more efficient where a collision on the

Paddington Canal swept away half of Smith's propeller

and as a result the boat actually gained speed. Originally, the wooden

propeller had been two complete turns. In

1839 I. K. brunel changed the design of the Great

Britain to screw propulsion. This iron boat could

acheive 11 knots with 1,500 horspower. Also in

1839 George Rennie patented his Conoidal propeller which

combined the ideas of increased pitch and multiple

threads. Then in 1869 C. Sharp of Philadelphia,

Pennsylvania patented a partially submerged propeller

with high pitch and cupped blades. Later the Wright Brothers

built a wind tunnel to develop a practical wing

shape. After testing hundreds of wing shapes they discovered an aerofoil section worked

best and formulated an efficient chord to length ratio

for their biplane wings, such as to enable the first

genuine powered flight.

James Watt of Scotland is generally credited with applying the first screw propeller to an engine at his Birmingham works, an early steam engine, beginning the use of

a hydrodynamic screw for propulsion.

Mechanical ship propulsion began with the steam ship. The first successful ship of this type is a matter of debate; candidate inventors of the 18th century include William Symington, the Marquis de Jouffroy, John Fitch and Robert Fulton, however William Symington's ship the Charlotte Dundas is regarded as the world's "first practical steamboat". Paddlewheels as the main motive source became standard on these early vessels (see Paddle steamer). Robert Fulton had tested, and rejected, the screw propeller.

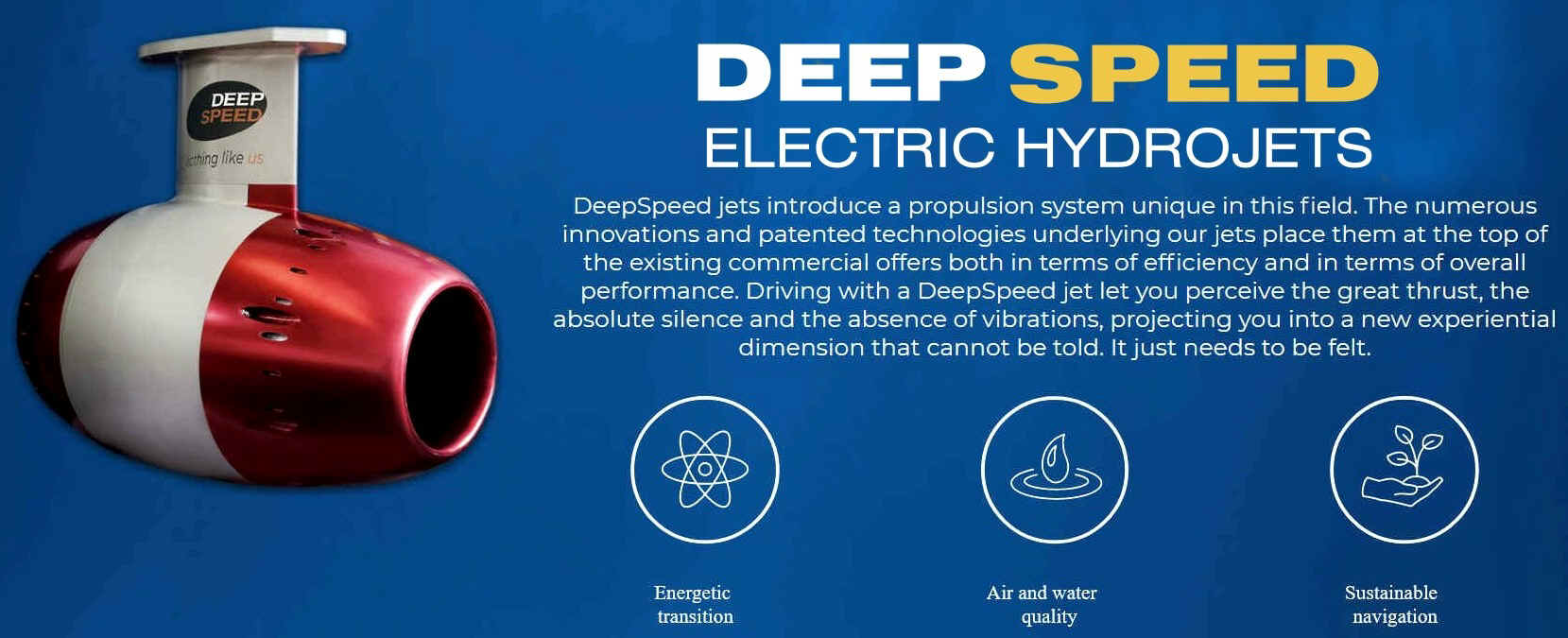

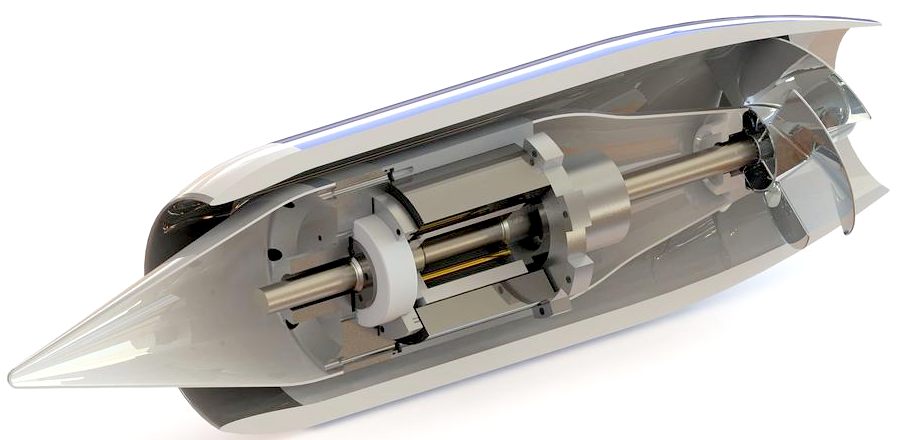

DEEP

SPEED -

From an idea to a product in record time, these electric hydro-jets from

Sealence in Italy are the business. In the coming age of zero emission

shipping, they hold the potential to revolutionize solar and wind powered

shipping, and hybrid yachts, tolling the death knell to conventional

propellers in many applications. In 2021 the company raised nearly €3

million Euros, to set them on the road to production. The Elizabeth Swann is

set to use these drives to get the most from renewable energy harvested form

nature.

The screw (as opposed to paddlewheels) was introduced in the latter half of the 18th century. David Bushnell's invention of the

submarine (Turtle) in 1775 used hand-powered screws for vertical and horizontal propulsion. The Bohemian (Austrian Empire) engineer Josef Ressel designed and patented the first practicable screw propeller in 1827. Francis Pettit Smith tested a similar one in 1836. In 1839, John Ericsson introduced practical screw propulsion into the United States. Mixed paddle and propeller designs were still being used at this time (vide the 1858 Great Eastern).

The screw propeller replaced the paddles owing to its greater efficiency, compactness, less complex power transmission system, and reduced susceptibility to damage (especially in battle)

Initial designs owed much to the ordinary screw from which their name derived - early propellers consisted of only two blades and matched in profile the length of a single screw rotation. This design was common, but inventors endlessly experimented with different profiles and greater numbers of blades. The propeller screw design stabilized by the 1880s.

In the early days of steam power for ships, when both paddle wheels and screws were in use, ships were often characterized by their type of propellers, leading to terms like screw steamer or screw sloop.

Propellers are referred to as "lift" devices, while paddles are "drag" devices.

SIZING

Marine

propeller sizes are always specified by diameter

and pitch (diameter x pitch) with the diameter

dimension specified first. For example: a 15 x 12 propeller has a

15" diameter and a 12" pitch. Normally, these are the only

dimensions given in a prop size, which is

unfortunate because there are other

characteristics of the prop you need to consider

when selecting the size. You should always start

your search with the diameter and pitch of the

prop first then work from there.

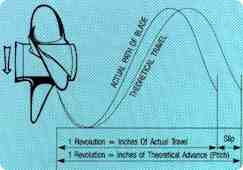

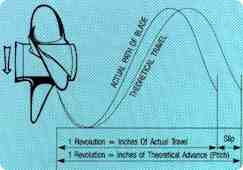

PITCH

Pitch is measured in inches and it is a

theoretical measure of how far the propeller

should move through the water in one revolution if

there was no slippage at all. For example, an

18" pitch prop would move 18" forward in

one revolution (provided there was no slippage).

The primary effect of pitch on your

performance is the same as the gear-shift in your

car. Higher pitch numbers are like the higher

gears (4th and 5th) in your car, more speed but

less acceleration. Lower pitches are like lower

gears (2nd and 3rd): more acceleration but less

top speed.

DIAMETER

Diameter is just what you think it is: the

diameter of the spinning prop. You can quickly

check the diameter by measuring from the center of

your prop nut to the tip of one of your prop

blades. Double the number you get to get your

diameter. Diameter can influence the speed you

get, but it has its greatest affect on your

acceleration and thrust. Bigger diameter is like

adding bigger tires to your car: more traction or

more appropriately, less slip. Larger diameters

put more load on your motor because they move more

water though so don't over do it. A blade moving

through water does experience drag. The less

blade there is (less diameter), the less the drag

will be. Provided your motor and prop produce

enough thrust, when you decrease your prop

diameter your speed will increase a bit because

there is less drag. Diameter is just what you think it is: the

diameter of the spinning prop. You can quickly

check the diameter by measuring from the center of

your prop nut to the tip of one of your prop

blades. Double the number you get to get your

diameter. Diameter can influence the speed you

get, but it has its greatest affect on your

acceleration and thrust. Bigger diameter is like

adding bigger tires to your car: more traction or

more appropriately, less slip. Larger diameters

put more load on your motor because they move more

water though so don't over do it. A blade moving

through water does experience drag. The less

blade there is (less diameter), the less the drag

will be. Provided your motor and prop produce

enough thrust, when you decrease your prop

diameter your speed will increase a bit because

there is less drag.

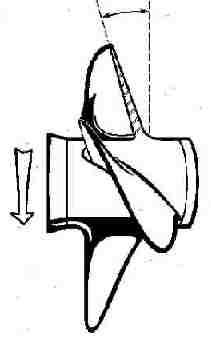

NUMBER

OF BLADES

How many blades

should your prop have? Three blade

propellers are the most common, but 4 and

even 5 blade props are available.

The immediate benefit to increasing your

propeller's blade count is increased thrust and a

smoother ride (Much like adding more cylinders to

your engine). Theoretically, the more blades

the lower the efficiency of the propeller.

How many blades

should your prop have? Three blade

propellers are the most common, but 4 and

even 5 blade props are available.

The immediate benefit to increasing your

propeller's blade count is increased thrust and a

smoother ride (Much like adding more cylinders to

your engine). Theoretically, the more blades

the lower the efficiency of the propeller.

However, increased blade count generally means that each

blade no longer has to deal with as much

horsepower and consequently the blades can be made

a bit thinner which improves their individual

efficiency. For example, on a three blade prop

running on a 300HP motor, each blade has to handle

a 100 hp each. On a 4 blade prop on the same

motor, each blade only has to handle 75 HP! This

allows the designer to build a prop with a thinner

blade without sacrificing stiffness or strength.

Unfortunately, the overall efficiency of a

multi-bladed propeller is reduced when the

blades are forced to run through confused waters -

increasing drag. Equally, drag rises to the square

(approximately) of speed. Also, a narrow

blade, just like a thinner blade passes through

the water with less drag. Ideally,

therefore, we want a thin section, narrow twin

blade, revolving as slowly as possible.

Which is just not practical for most boating

applications.

CUPPING

Cupping is added to most propeller blades to

improve the propeller's bite on the water and

decrease slippage. It is most commonly seen on the

trailing edge of the blade. Usually the effect of

cupping makes the prop perform like a higher pitch

propeller, but it does enhance your thrust as

well. In addition, cup reduces a prop's tendancy

to ventilate or slip. Custom prop builders often

use aggressive degrees of cupping to fix slippage

problems on large diameter, low pitch props on

certain boating applications. Cupping is added to most propeller blades to

improve the propeller's bite on the water and

decrease slippage. It is most commonly seen on the

trailing edge of the blade. Usually the effect of

cupping makes the prop perform like a higher pitch

propeller, but it does enhance your thrust as

well. In addition, cup reduces a prop's tendancy

to ventilate or slip. Custom prop builders often

use aggressive degrees of cupping to fix slippage

problems on large diameter, low pitch props on

certain boating applications.

Most props you will encounter are cupped. Most

likely, you will only see an uncupped propeller in

performance applications. On smaller outboards,

which produce most of their power in the upper

third of their RPM range, an uncupped prop with a

semi-cleaver design often produces better

performance. To get maximum performance, it is

necessary to get the motor spinning up in this

range as quickly as possible. An uncupped prop

loads the motor a bit less, allowing the rpm to

build more quickly. This enables you to operate

your motor in the meat of its powerband where

you'll get maximum power. You will notice faster

hole-shot, quicker acceleration, and often times,

higher top speeds with these semi-cleaver,

uncupped style blades. If you are currently

running a cupped style propeller and

want to improve your overall performance consider

trying a semi-cleaver design. Generally, when

switching to an uncupped semi-cleaver style prop,

you can up the pitch 2 inches and still have

better hole-shot, quicker acceleration and often

better top speed! Cup can also provide

additional bow lift when utilized on the rake line of

the prop.

Applying cup to the trailing edge of the prop

along the pitch line will increase the effective pitch

of the propeller. A standard cup will typically result

in a decrease of 200 to 400 rpm's. This usually means a

decrease in pitch of 1 to 2 inches is required to run a

cupped propeller in place of an uncupped wheel.

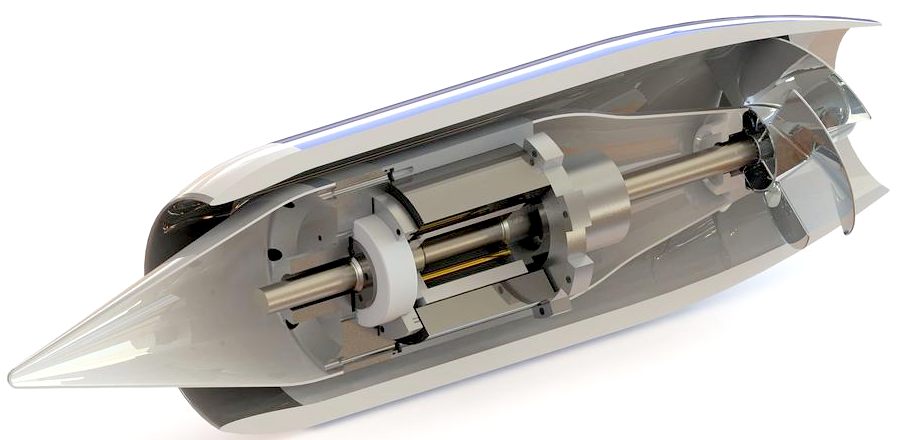

CONTRA

ROTATING IMPELLERS - Traditional single propeller systems generate

thrust by accelerating water in the axis of the propeller shaft. However,

the water discharged by the propeller also rotates. This is due, in part, to

the friction between the surface of the propeller and the water. This

rotational component does not produce thrust, but it does consume energy. By

turning the propellers in opposite directions, the efficiency of the a

thruster becomes 10 to 15% greater than that of single propeller systems.

This has to be offset by frictional losses in the bearings and gears, but

overall there is a gain with additional cost and complexity. Another method

used to increase the efficiency of water (jet) pumps is a fixed stator. Torpedoes

that have to travel at high speed use contra-rotating propellers for this

reason.

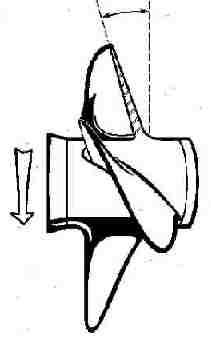

BLADE

RAKE

Blade

Rake represents the angle of attachment of the

blade to the hub of the propeller. This is not

to be confused with the pitch, which is a

measure of the twist or screw progression.

The amount of rake built into a propeller blade is

not something many people consider when buying a

new prop, but it can be just what the Dr. ordered

in some cases. Rake angle isn't an immediately

apparent thing to the untrained eye, but if the

propeller blade is cut down the cent er, it is

readily apparent. The biggest benefit

of a high rake design is a greater resistance to

ventilation. This allows you to trim the outdrive

up toward the surface more without the prop

ventilating as readily during tight manuevering.

You should seriously consider using a high rake

propeller if ventilation is a problem for you. er, it is

readily apparent. The biggest benefit

of a high rake design is a greater resistance to

ventilation. This allows you to trim the outdrive

up toward the surface more without the prop

ventilating as readily during tight manuevering.

You should seriously consider using a high rake

propeller if ventilation is a problem for you.

If you have a large boat like a house or deck boat

a high rake prop may not be the best choice

because it does not produce as much reverse

thrust. This may reduce your ability to manuever

your vessel at low speeds making your boat more

difficult to dock.

Higher rake normally improves performance in

ventilating or cavitating situations (high

engine elevations and high trim angles).

Additionally, higher rake can provide higher bow

lift, which will frequently improve speed. Low

rake blades are typically used on motors with

propellers running fully submerged, typically

carrying moderate to heavy loads. The rake angle

can either be straight or the average angle of a

parabolic curve.

EFFICIENCY

Not

many manufacturers quote the efficiency of their

propellers and even fewer customers ask. The

efficiency of a propeller is defined as the power

coming out of a prop divided by the power going

in:

Power

out

--------------

X 100

For a solar powered boat, efficiency is probably

the most important statistic.

Power

in

BLADE

THICKNESS

(thinner blades cut better)

Why is

Stainless Steel the first choice for high

performance props? A: It is much stronger and far

stiffer than aluminum, but that's not the whole

answer. The higher strength of stainless means

that the blades can be made thinner and that is

where the performance benefit comes from: thin

blades slice through the water more efficiently

than thicker blades. As a result stainless props

produce a couple more mph over even the best

aluminum designs.

This Design

concept is part of the reason our 4-Blade

propellers and our uncupped "XB" style

3-Blade propellers outperform our Standard 3-Blade

Designs. By incorporating a thinner blade

cross-section, those props cut through the water

with less resistance. There is a compromise to be

made though and that compromise is in durability.

The thinner blades are faster, but they are not as

durable as our thicker blade designs. If you run

up and down a shallow river and hit things

frequently, you may be happier sacrificing some

performance to run the tougher blades. If you

typically run in the ocean with little chance of a

strike, you may prefer the added speed of our

thinner blades.

WHIRL WIND AIR

BOAT PROPELLERS

Whirl Wind AB Series

of airboat propellers are designed for maximum

performance and durability. The

AB series offers excellent all-around

performance; and for those times you

might need that extra boost, it has the static

thrust you require.

With the serious airboater in mind, the AB

Series has been designed to make pitch

change in the field quick and easy - just

minutes, 1 tool, 1 person and you're off!

And because the blades are modular, you can

replace individual blades when needed rather

than replacing the whole propeller system.

Whirl

Wind

has been producing propeller products for

Unlimited category aerobatic champions and

top airshow performers, as well as for the

U.S. Air Force Unmanned Aerial Vehicles (UAV).

With this rich engineering and composite

manufacturing background, Whirl Wind has

applied their know-how in aviation to the

airboat world with the development of the

all-composite airboat propeller system - the

AB Series. The AB Series is

an airboat

propeller system with graphite

composite blades, offered in two,

three or four bladed designs and available handed to

eliminate sideways thrust (on twin engine setups).

mailto:wwpc@whirlwindpropellers.com?subject=airboat

propeller question

Thick Nickel Leading Edges: Nickel is twice as hard as stainless steel, and

has superior abrasion and impact resistance. A

protective metal leading edge can save composite propeller blades

from destruction should driftwood, etc, go through the propeller --

in this case a 5/8" wrench.

This blade was able to be repaired to like-new

condition for just under $100. Foreign object

damage like this would destroy most any other

composite propeller.

Unusual

variable pitch surface piercing propeller on the Turanor PlanetSolar

ELIZABETH

SWANN'S DESIGN COMPROMISE

As

mentioned above, the

propellers on the Elizabeth

Swann must be efficient above

all. We are looking to achieve 70%

efficiency. So far our tests have exceeded our

target figure up to about one third full size.

Hence we are quietly confident. Having said this

our technical members will not be completely happy until

a full size propeller demonstrates the same efficiency. The

basic theory of propellers tells a single bladed prop is

theoretically the most efficient. In practice a twin

blade is the most practical to reduce vibration. The more blades the

more each other blade introduces turbulent flow into the

equation. The slower a blade moves through the

water the less the drag and the smaller a blade's surface

area, (narrow) the less the frictional drag. It

would seem from the above we are looking for a slowly

revolving propeller with low drag and a small surface

area. Provided we know the speed our vessel will

cruise and the thrust needed to overcome hull drag, we

can then calculate for the most efficient

propeller. Again, this is not quite so straight

forward because there are size and other mechanical

limitations. For this reason commercial propellers

usually have three small blades revolving at quite high

speeds of 3,000 rpm or more. On the other end of

the scale we have huge Tug propellers revolving @ only

500 rpm. The

material a propeller is made from can seriously improve

its performance. For example, a cast aluminium

propeller will corrode more and have thicker sections

than a stainless steel prop. Then again the

stainless prop will cost more. In some

applications carbon fibre is cost effective, as in human

powered craft. Assuming

cost will not prevent the use of exotic materials, the

blade section, pitch and swept area are important to

producing the right propeller for the job. No

doubt we will experiment with quite a few full size

props in deciding on the final pair.

LINKS

& REFERENCE

http://sut.org/

http://lianinno.com/underwater-thrusters/

https://www.marinelink.com/news/breakthrough-electrical354225

https://www.ilsole24ore.com/art/deepspeed-l-idrogetto-elettrico-che-mandera-pensione-l-elica-AC9KCid

https://www.copenhagensubsea.com/

https://plugboats.com/an-italian-hydrojet-to-revolutionize-electric-boats/

https://plugboats.com/amazing-new-electric-boat-motor-based-on-fish-fins/

https://en.wikipedia.org/wiki/Underwater_thruster

https://en.wikipedia.org/wiki/Pump-jet

https://www.instructables.com/id/ROV-Thruster-105-Lbs-From-DT700-Brushless-Motor/

http://www.gepowerconversion.com/

PROPELLER

LINK PAGE

ZERO

EMISSION YACHT - The Elizabeth Swann is a solar and wind powered

trimaram. Probably the most advanced vessel in the world technologically.

A

taste for adventure

A

heartwarming adventure: whalers V conservationists, with a happy ending

for all

|

Diameter is just what you think it is: the

diameter of the spinning prop. You can quickly

check the diameter by measuring from the center of

your prop nut to the tip of one of your prop

blades. Double the number you get to get your

diameter. Diameter can influence the speed you

get, but it has its greatest affect on your

acceleration and thrust. Bigger diameter is like

adding bigger tires to your car: more traction or

more appropriately, less slip. Larger diameters

put more load on your motor because they move more

water though so don't over do it. A blade moving

through water does experience drag. The less

blade there is (less diameter), the less the drag

will be. Provided your motor and prop produce

enough

Diameter is just what you think it is: the

diameter of the spinning prop. You can quickly

check the diameter by measuring from the center of

your prop nut to the tip of one of your prop

blades. Double the number you get to get your

diameter. Diameter can influence the speed you

get, but it has its greatest affect on your

acceleration and thrust. Bigger diameter is like

adding bigger tires to your car: more traction or

more appropriately, less slip. Larger diameters

put more load on your motor because they move more

water though so don't over do it. A blade moving

through water does experience drag. The less

blade there is (less diameter), the less the drag

will be. Provided your motor and prop produce

enough  Cupping is added to most propeller blades to

improve the propeller's bite on the water and

decrease slippage. It is most commonly seen on the

trailing edge of the blade. Usually the effect of

cupping makes the prop perform like a higher pitch

propeller, but it does enhance your thrust as

well. In addition, cup reduces a prop's tendancy

to ventilate or slip. Custom prop builders often

use aggressive degrees of cupping to fix slippage

problems on large diameter, low pitch props on

certain boating applications.

Cupping is added to most propeller blades to

improve the propeller's bite on the water and

decrease slippage. It is most commonly seen on the

trailing edge of the blade. Usually the effect of

cupping makes the prop perform like a higher pitch

propeller, but it does enhance your thrust as

well. In addition, cup reduces a prop's tendancy

to ventilate or slip. Custom prop builders often

use aggressive degrees of cupping to fix slippage

problems on large diameter, low pitch props on

certain boating applications.

er, it is

readily apparent. The biggest benefit

of a high rake design is a greater resistance to

ventilation. This allows you to trim the outdrive

up toward the surface more without the prop

ventilating as readily during tight manuevering.

You should seriously consider using a high rake

propeller if ventilation is a problem for you.

er, it is

readily apparent. The biggest benefit

of a high rake design is a greater resistance to

ventilation. This allows you to trim the outdrive

up toward the surface more without the prop

ventilating as readily during tight manuevering.

You should seriously consider using a high rake

propeller if ventilation is a problem for you.